Customized Double-sided Printing Corrugated Board Snacks Box Food Packing Box

Description

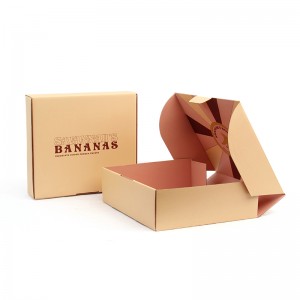

This is a 3 layers E-flute corrugated food packaging box, the thickness of materials is around 2mm. It can be used to pack and delivery snacks, pizza, cup-cake, sushi, frozen dessert, etc. The outside and inside of the box is offset printing, there is matte film coated on the surface, we call it matte lamination.

Basic Info.

|

Product Name |

Food Packing Box |

Surface Treatment |

Matte Lamination |

|

Box Style |

Folding Corrugated Pizza Box |

Logo Printing |

Customized Logo |

|

Material Structure |

White cardboard paper/Duplex paper is mounted together with corrugated board. |

Origin |

Ningbo city, China |

|

Weight |

lightweight box, 32ECT |

Sample type |

Printing sample, or no print. |

|

Shape |

Rectangle |

Sample Lead Time |

2-5 working days |

|

Color |

CMYK Color, Pantone Color |

Production Lead Time |

12-15 natural days |

|

Printing mode |

Offset Printing |

Transport Package |

Standard export carton |

|

Type |

Double-sided Printing Box |

MOQ |

2,000PCS |

Detailed Images

These details are used to show the quality, such as materials, printing and surface treatment.

Customer Question & Answer

Please contact customer service for more information.

Your response of following questions will help us recommend the most suitable package.

Material Structure and Application

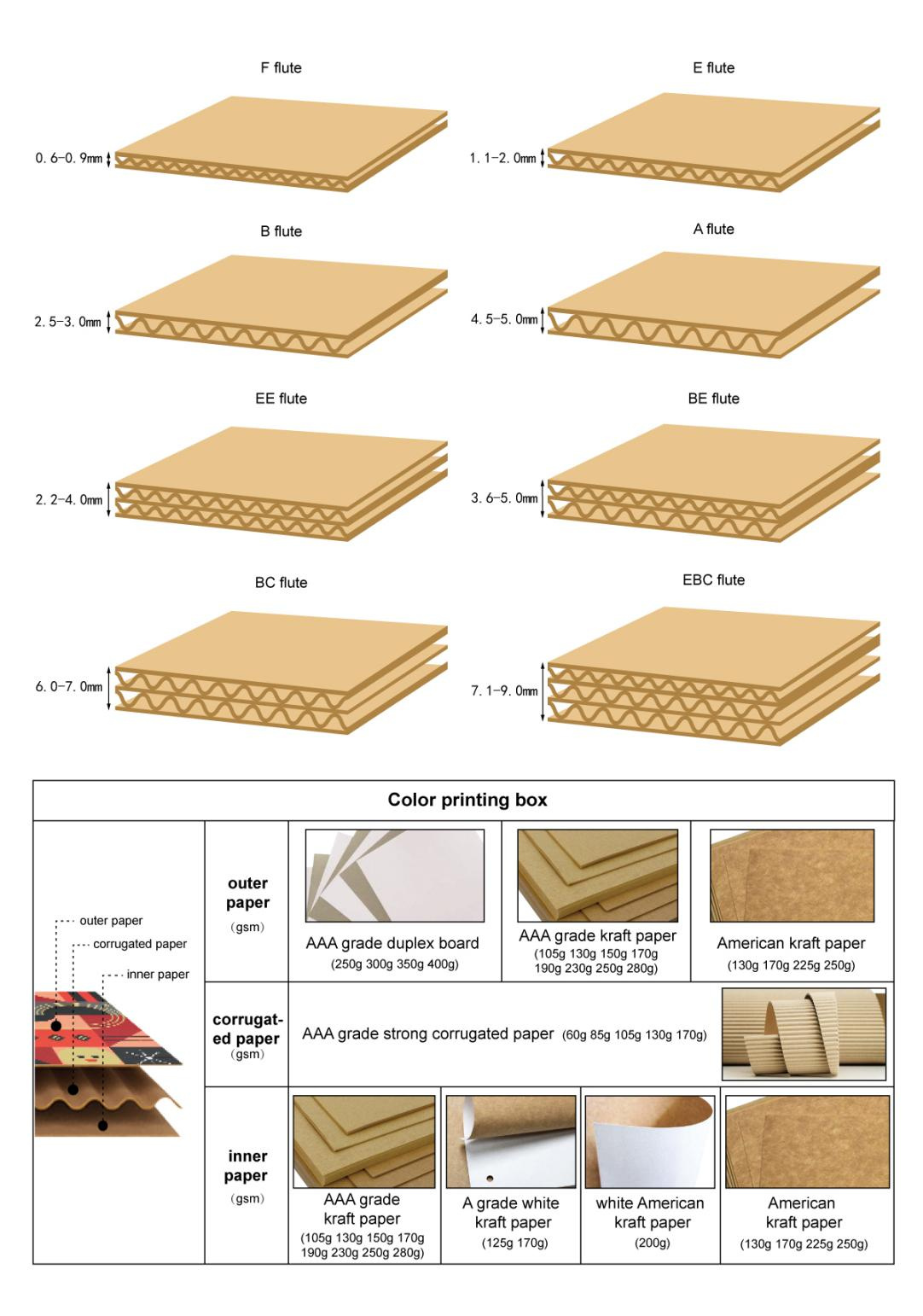

Corrugated paperboard can be divided into 3 layers, 5 layers and 7 layers according to the combined structure.

The thicker “A Flute” corrugated box has better compressive strength than “B Flute” and “C Flute”.

“B Flute” corrugated box are suitable for packing heavy and hard goods, and are mostly used for packing canned and bottled goods. “C Flute” performance is close to “A Flute”. “E Flute” has the highest compression resistance, but its shock absorption capacity is slightly poor.

Corrugated Paperboard Structure Diagram

Packaging Applications

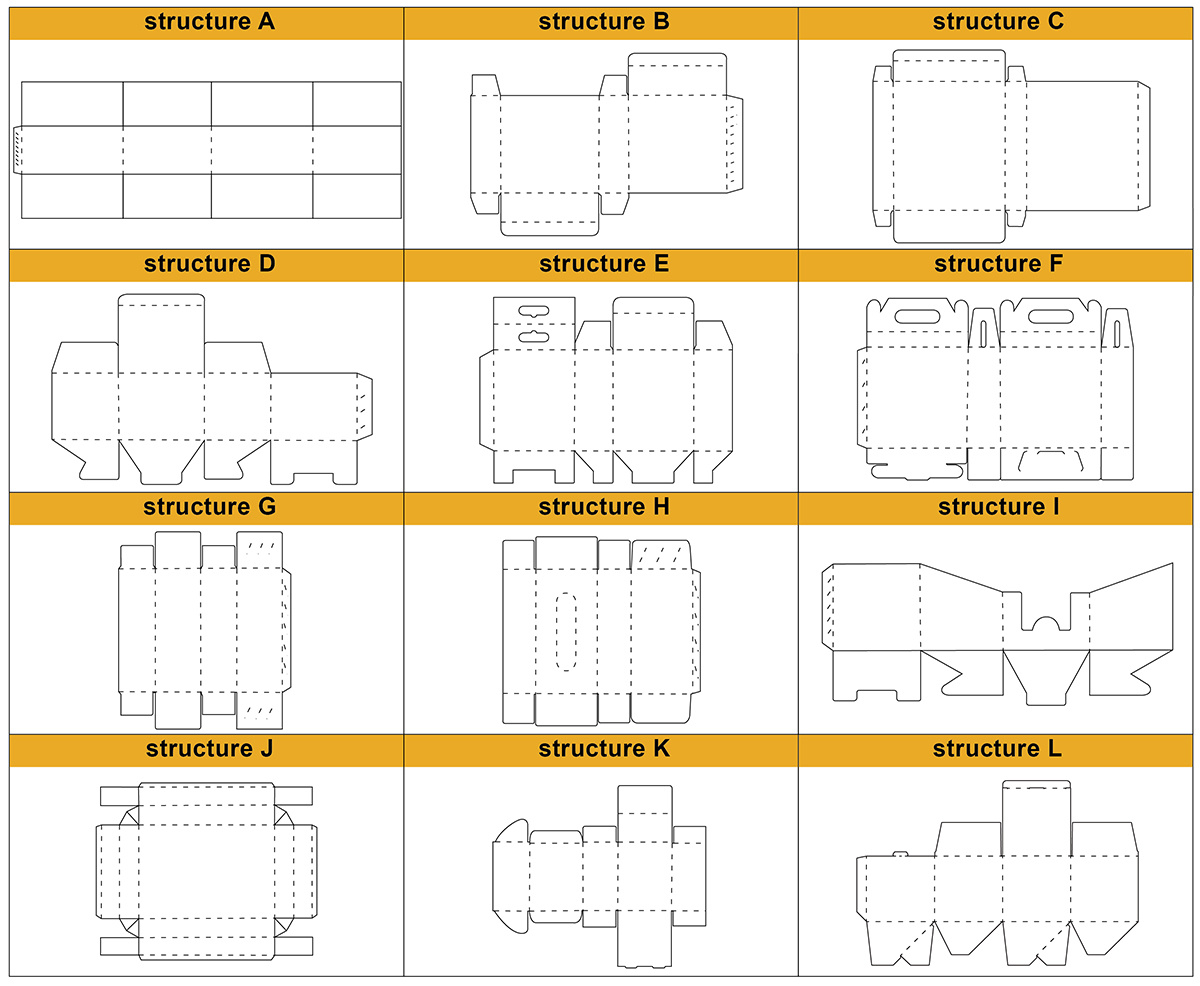

Box Type and Finish Surface

These box types are used for reference, it can be customized as well.

The surface treatment process of printed products generally refers to the post-processing process of printed products, in order to make the printed products more durable, convenient for transportation and storage, and look more high-end, atmospheric and high-grade. Printing surface treatment includes: lamination, spot UV, gold stamping, silver stamping, concave convex, embossing, hollow-carved, laser technology, etc.

Common Surface Treatment As Follows

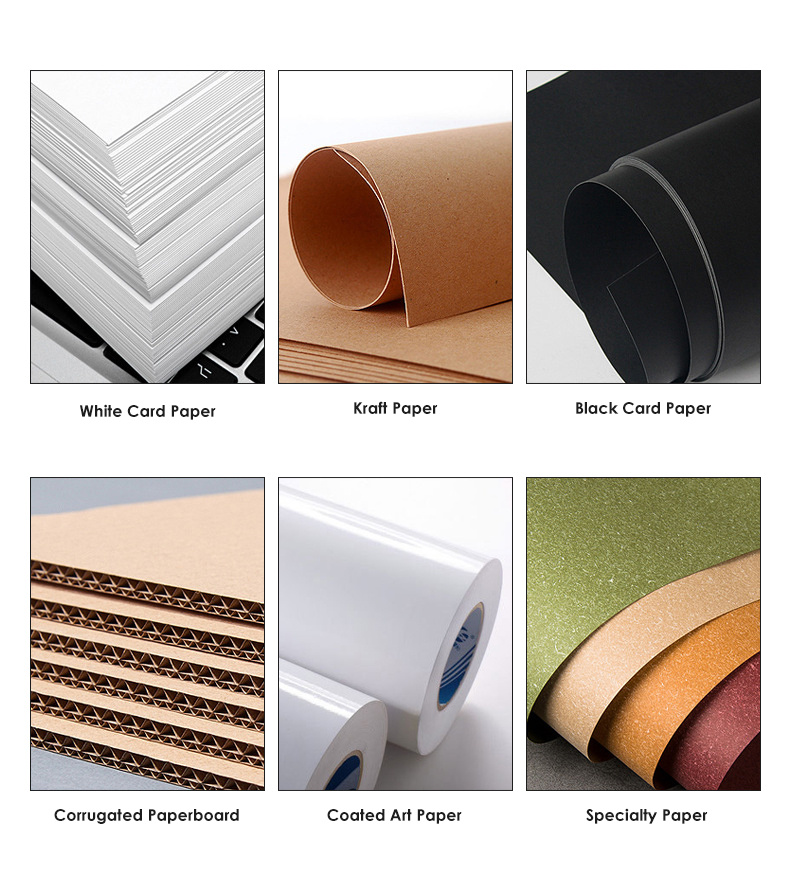

Paper Type

White Card Paper

Both sides of the white card paper are white. The surface is smooth and flat, the texture is hard, thin and crisp, and can be used for double-sided printing. It has relatively uniform ink absorption and folding resistance.

Kraft Paper

Kraft paper is flexible and strong, with high breaking resistance. It can withstand large tension and pressure without cracking.

Corrugated Paperboard

The advantages of corrugated paperboard are: good cushioning performance, light and firm, sufficient raw materials, low cost, convenient for automatic production, and low packaging cost. Its disadvantage is poor moisture-proof performance. Humid air or long-term rainy days will cause the paper to become soft and poor.

Coated Art Paper

Coated paper has smooth surface, high whiteness and good ink absorption performance. It is mainly used for printing advanced picture books, calendars and books, etc.