Factory OEM Custom Recycled Luxury Magnetic Kraft Packaging Grey Board Folding Snap Classic Gift Box

Description

A suitable gift box will improve the quality of the product and play a good role in promoting the enterprise.

Featured gift boxes are more likely to leave a deep impression and make consumers want to buy.

Color art paper can be used to paste the outside and interior of a box or double offset printing paper with an OEM design.

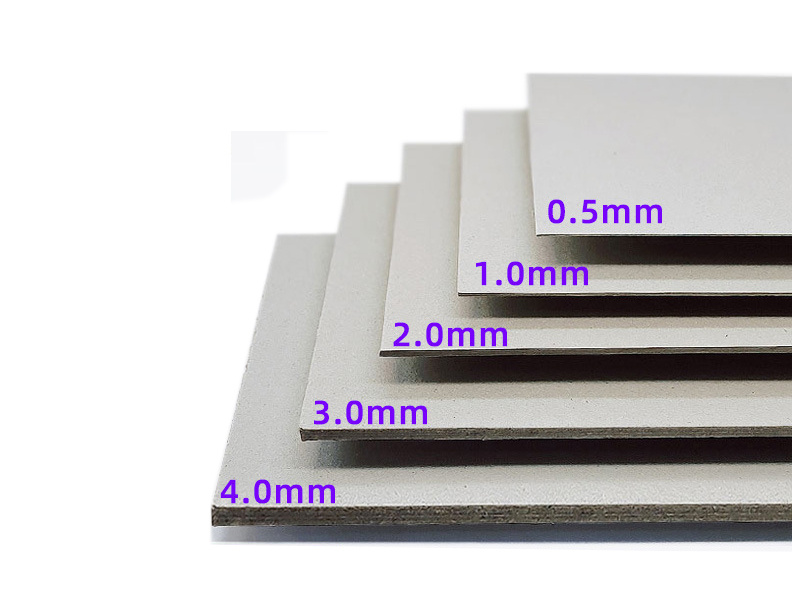

It usually in 1mm, 1.5 mm, 2mm, 2.5 mm gray board.

Basic Info

|

Product Name |

Magnetic Cardboard Box |

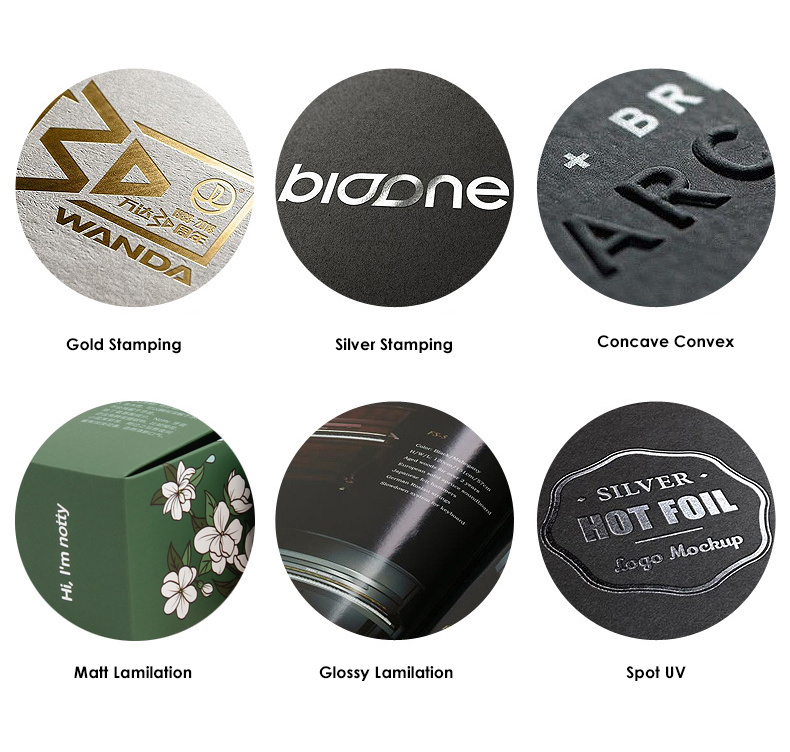

Surface Handling |

Glossy lamination, matte lamination, Embossed, Spot UV |

|

Box Style |

OEM Design |

Logo Printing |

Customized Logo |

|

Material thickness |

1 mm, 1.5mm, 2 mm, 2.5 gray board |

Origin |

Ningbo |

|

Materials type |

Single gray board, double gray board, single white board, single black board... |

Sample |

Accept custom samples |

|

Shape |

Rectangle |

Sample Time |

7-10 Working Days |

|

Color |

CMYK Color, Pantone Color |

Production Lead Time |

10-15 working days based on quantity |

|

Printing |

Offset Printing, UV Printing |

Transport Package |

Strong 5 ply Corrugated Carton |

|

Type |

Single Printing Box |

MOQ |

2000PCS |

Detailed Images

The process of making gift boxes is multi process and multi step. Due to the long process, the control of each link is related to the quality of the entire product.

Full automatic and semi-automatic production of gift boxes can not only improve efficiency, but also improve quality.

Production process of book type gift box.

Material Structure and Application

Grey board paper is an environmental protection packaging material. It is made of recycled raw materials with low price and high quality. If paper is considered to produce printing products, it is a good choice.

Grey cardboard has the characteristics of smooth paper surface, good stiffness, no easy deformation and strong hardness.

The edge shall be neat when cutting with numerical control machine.

The thickness of various specifications can meet different requirements.

Exquisite gift boxes can not only attract consumers' attention and increase sales, but also increase the added value of products and improve the quality of products.

Box Type and Finish Surface

Gift boxes come in a variety of varieties. Top and bottom combinations of sky and earth covers, embedded combinations of pull-out, left and right opening and shutting, and package combinations of books are all present inside the structure. These types set up the fundamental framework for gift boxes.

The box type as follow

Surface Treatment

The surface treatment process for printed things largely refers to the post-processing step that printed products go through to make them more transportable and storable, more durable, and to enhance their look by giving them a more upscale, ethereal, and high-grade feel. Surface treatments for printing include lamination, spot UV, gold stamping, silver stamping, concave-convex, embossing, hollow carving, laser technology, etc.

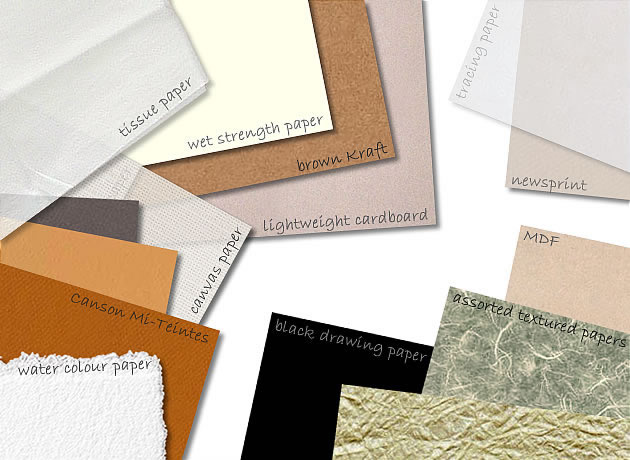

Paper Type

White Card Paper

Both sides of the white card paper are white. The surface is smooth and flat, the texture is hard, thin and crisp, and can be used for double-sided printing. It has relatively uniform ink absorption and folding resistance.

Kraft Paper

Kraft paper is flexible and strong, with high breaking resistance. It can withstand large tension and pressure without cracking.

Black Card Paper

Black cardboard is colored cardboard. According to different colors, it can be divided into red card paper, green card paper, etc. Its biggest drawback is that it can not print color, but it can be used for bronzing and silver stamping. The most commonly used is white card.

Corrugated Paperboard

The advantages of corrugated paperboard are: good cushioning performance, light and firm, sufficient raw materials, low cost, convenient for automatic production, and low packaging cost. Its disadvantage is poor moisture-proof performance. Humid air or long-term rainy days will cause the paper to become soft and poor.

Coated Art Paper

Coated paper has smooth surface, high whiteness and good ink absorption performance. It is mainly used for

printing advanced picture books, calendars and books, etc.

Specialty Paper

Special paper is made by special paper processing equipment and technology. The processed finished paper has rich colors and unique lines. It is mainly used for printing covers, decorations, handicrafts, hardcover gift boxes, etc.

Customer Question & Answer

Please contact customer service for more information.

Your response of following questions will help us recommend the most suitable package.

Grey board paper is an environmental protection packaging material. It is made of recycled raw materials with low price and high quality. If paper is considered to produce printing products, it is a good choice.

Grey cardboard has the characteristics of smooth paper surface, good stiffness, no easy deformation and strong hardness.

The edge shall be neat when cutting with numerical control machine.

Gift boxes come in a variety of varieties. Top and bottom combinations of sky and earth covers, embedded combinations of pull-out, left and right opening and shutting, and package combinations of books are all present inside the structure. These types set up the fundamental framework for gift boxes.

The box type as follow

Surface Treatment

The surface treatment process for printed things largely refers to the post-processing step that printed products go through to make them more transportable and storable, more durable, and to enhance their look by giving them a more upscale, ethereal, and high-grade feel. Surface treatments for printing include lamination, spot UV, gold stamping, silver stamping, concave-convex, embossing, hollow carving, laser technology, etc.

Paper Type

White Card Paper

Both sides of the white card paper are white. The surface is smooth and flat, the texture is hard, thin and crisp, and can be used for double-sided printing. It has relatively uniform ink absorption and folding resistance.

Kraft Paper

Kraft paper is flexible and strong, with high breaking resistance. It can withstand large tension and pressure without cracking.

Black Card Paper

Black cardboard is colored cardboard. According to different colors, it can be divided into red card paper, green card paper, etc. Its biggest drawback is that it can not print color, but it can be used for bronzing and silver stamping. The most commonly used is white card.

Corrugated Paperboard

The advantages of corrugated paperboard are: good cushioning performance, light and firm, sufficient raw materials, low cost, convenient for automatic production, and low packaging cost. Its disadvantage is poor moisture-proof performance. Humid air or long-term rainy days will cause the paper to become soft and poor.

Coated Art Paper

Coated paper has smooth surface, high whiteness and good ink absorption performance. It is mainly used for

printing advanced picture books, calendars and books, etc.

Specialty Paper

Special paper is made by special paper processing equipment and technology. The processed finished paper has rich colors and unique lines. It is mainly used for printing covers, decorations, handicrafts, hardcover gift boxes, etc.