OEM Design Logo Printing Carton Cooking Packaging Box for Household appliance Toaster Citrus Juicer

Description

Automatic forming structure. When shipping, fasten the lock catch to make the cover more secure and firm.

The printing effect of offset printing is better, and more printing details can be displayed.

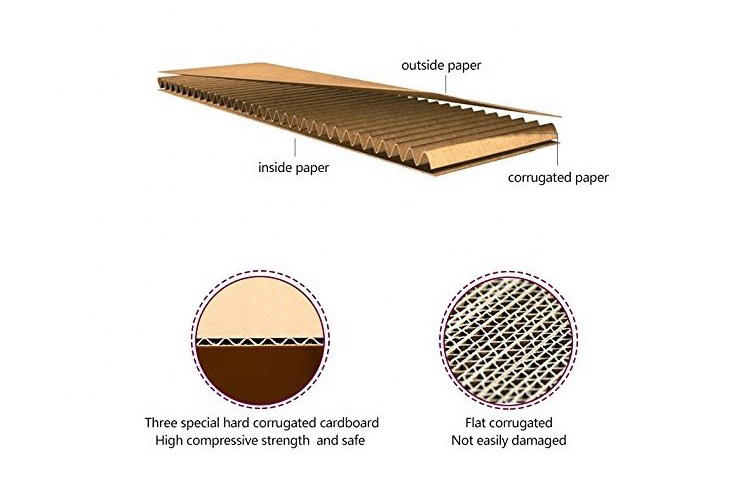

The sturdy corrugated cardboard has three or five layers, which can support household appliances of various weights and sizes.

Basic Info.

|

Product Name |

Cookware Packaging Box |

Surface Handling |

Glossy lamination, Matt Lamination |

|

Box Style |

Folding Corrugated Box |

Logo Printing |

Customized Logo |

|

Material Structure |

White Board + Corrugated Paper + White Board / kraft paper |

Origin |

Ningbo |

|

Weight |

0.3-0.5kg |

Sample |

Accept custom samples |

|

Shape |

Rectangle |

Sample Time |

5-8 Working Days |

|

Color |

CMYK Color, Pantone Color |

Production Lead Time |

8-12 days based on quantity |

|

Printing |

Offset Printing |

Transport Package |

Strong 3 ply/5 ply Corrugated Carton |

|

Type |

Single /Two-sided Printing Box |

MOQ |

2000PCS |

Package size per unit product:175 ×175×200 mm; 240 ×240 ×300 mm;220 ×220 ×310 mm.

Gross weight per unit product:0.3-0.6kg

Detailed Images

The structural designer will draw the exact size and structure of the box according to your specifications. You can design the packaging according to the structure diagram of the box. In order to make the finished packaging box, we will print it according to your design.

The products waiting for shipment are arranged orderly.

Material Structure and Application

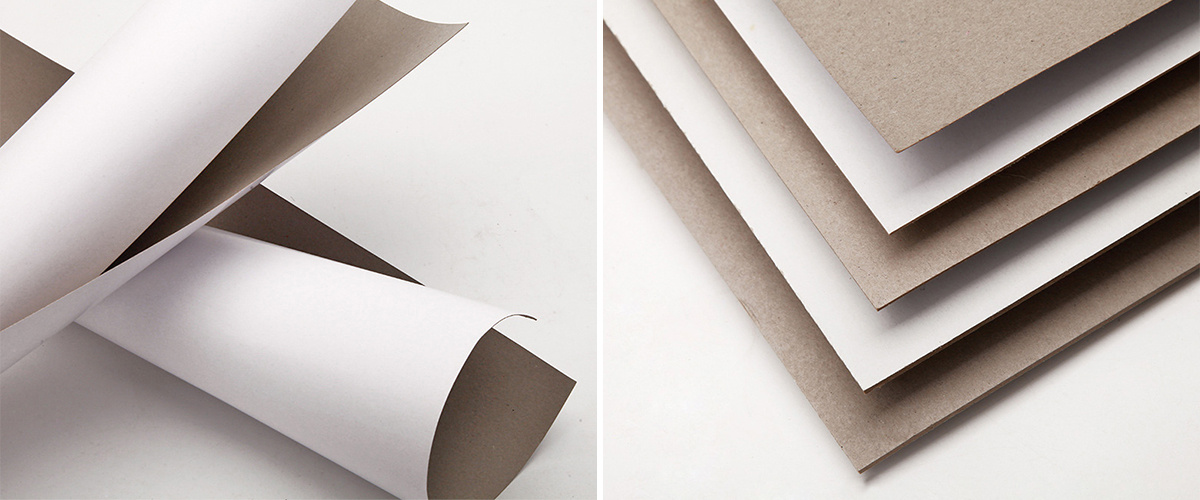

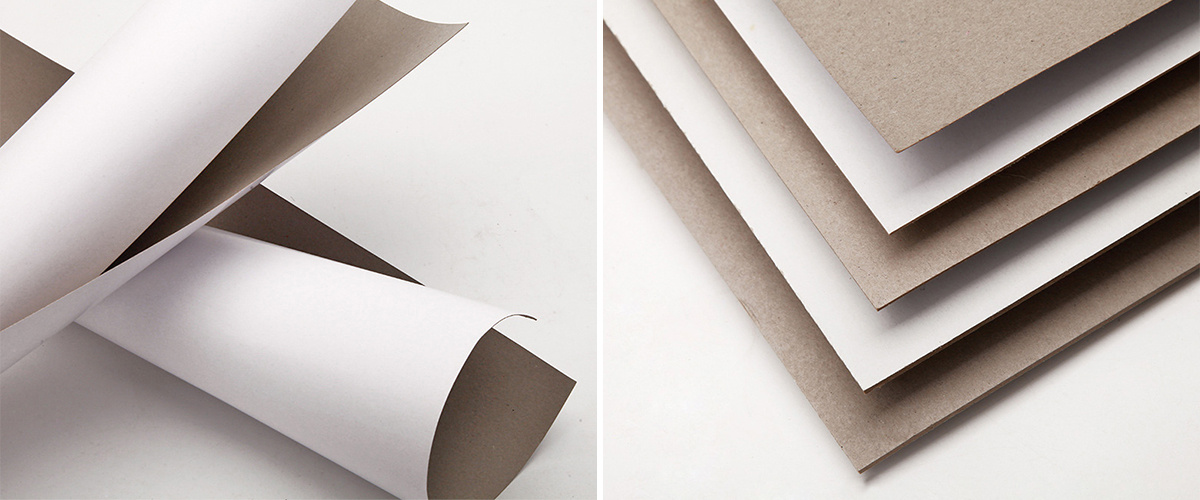

The packaging material consists of outer paper, medium paper and inner paper.

The outer paper is white board paper or white cardboard. After printing on the outer paper, it is pasted on the corrugated board by the auto-laminating machine.

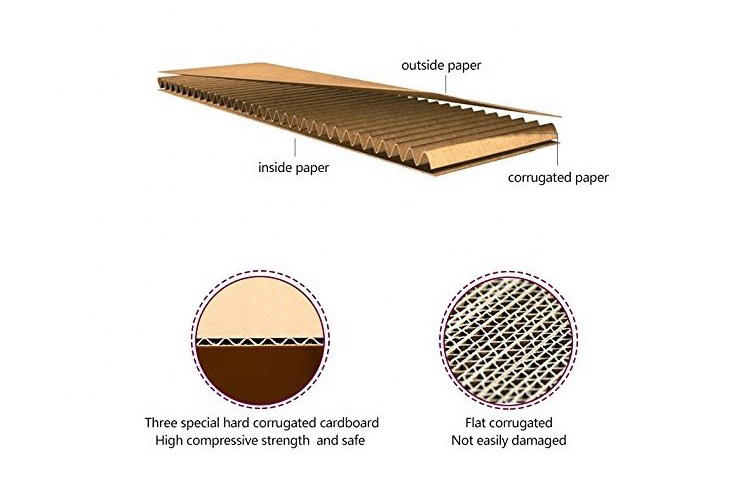

Depending on the overall structure, corrugated paperboard can be split into 3 layers, 5 layers, and 7 layers.

Three parts can be as customized size and weight. Outside & inside paper can be printed OEM design and color.

Face paper material - coated duplex board

Face paper material - card paperboard.

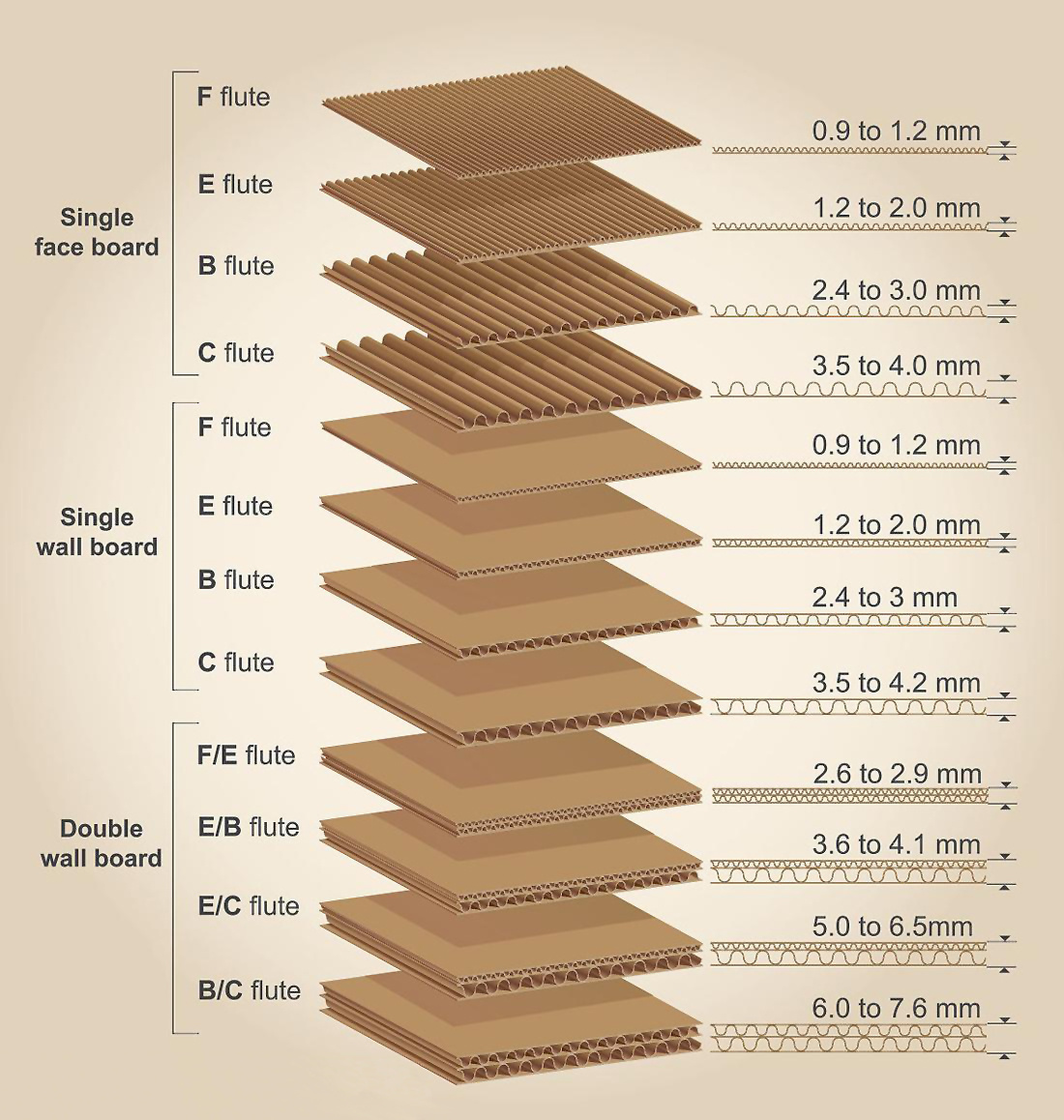

Corrugated Cardboard Structure

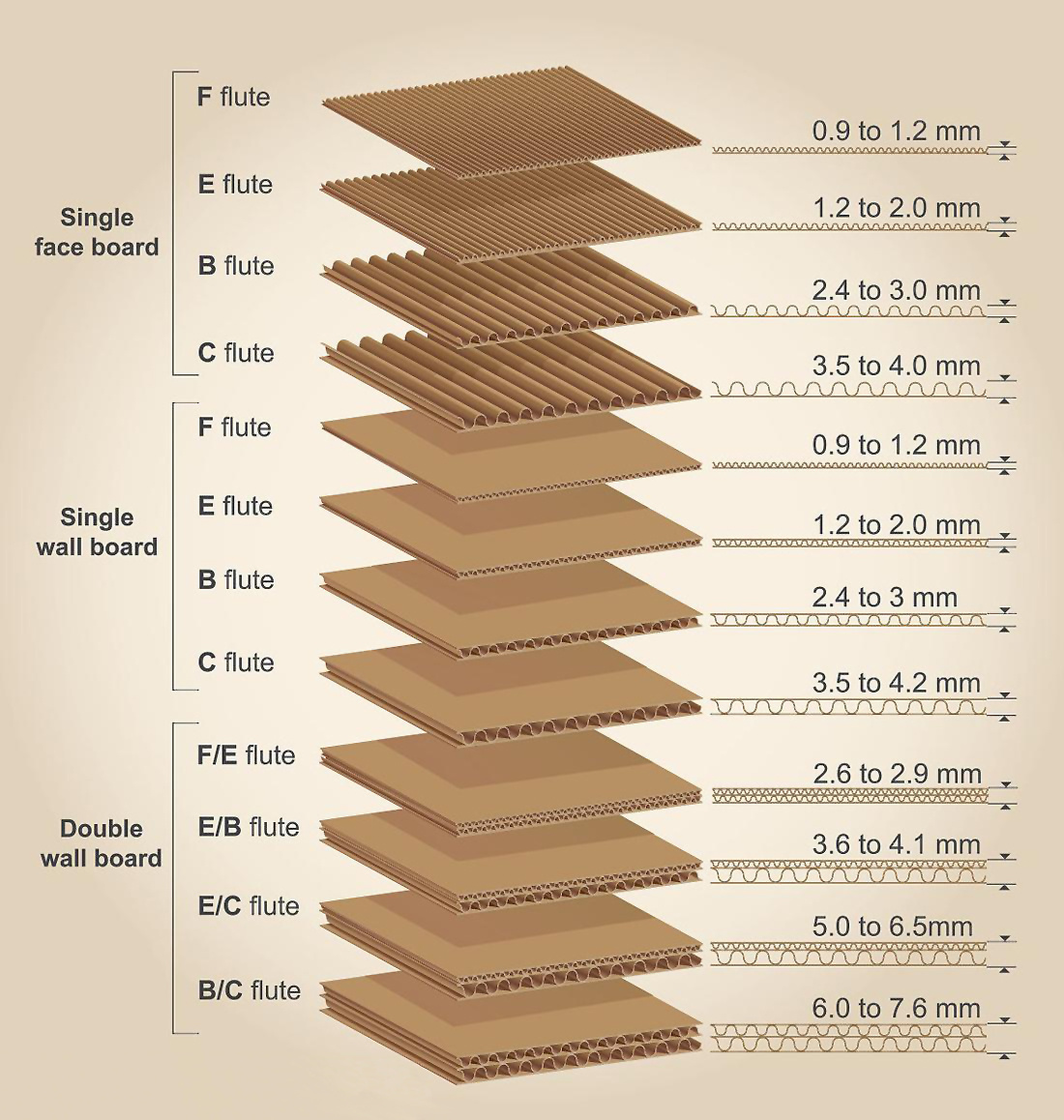

Corrugated Cardboard Type

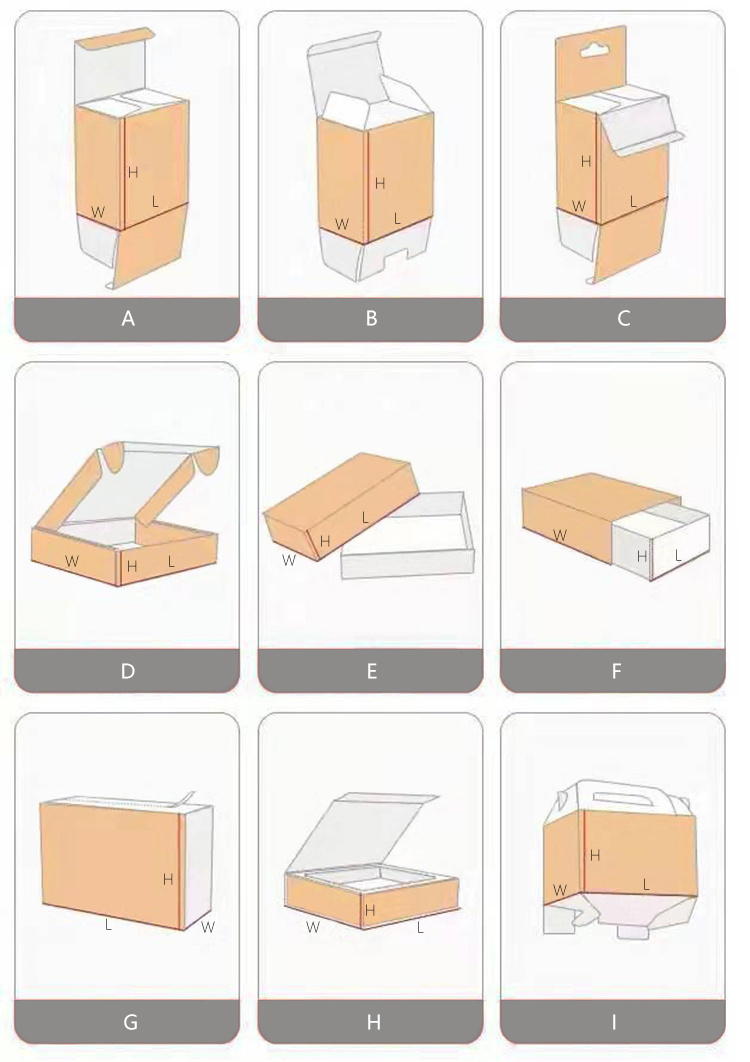

Packaging Applications

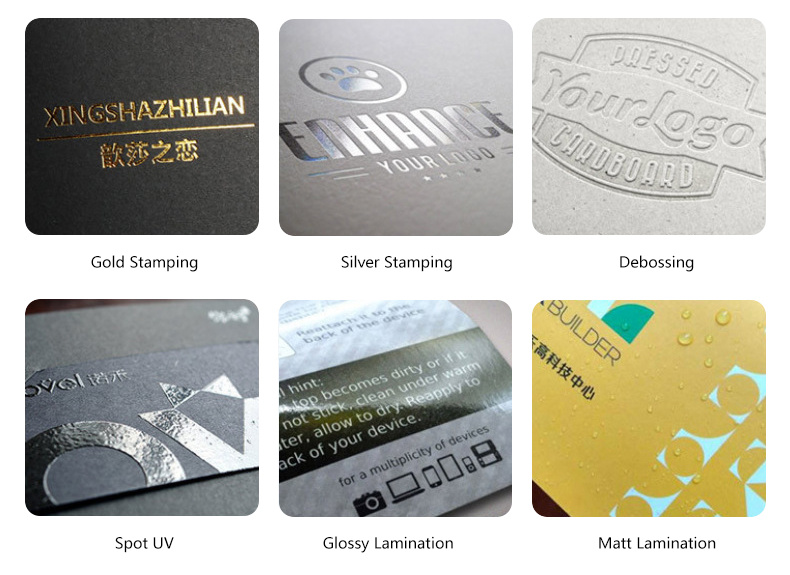

Box Type and Finish Surface

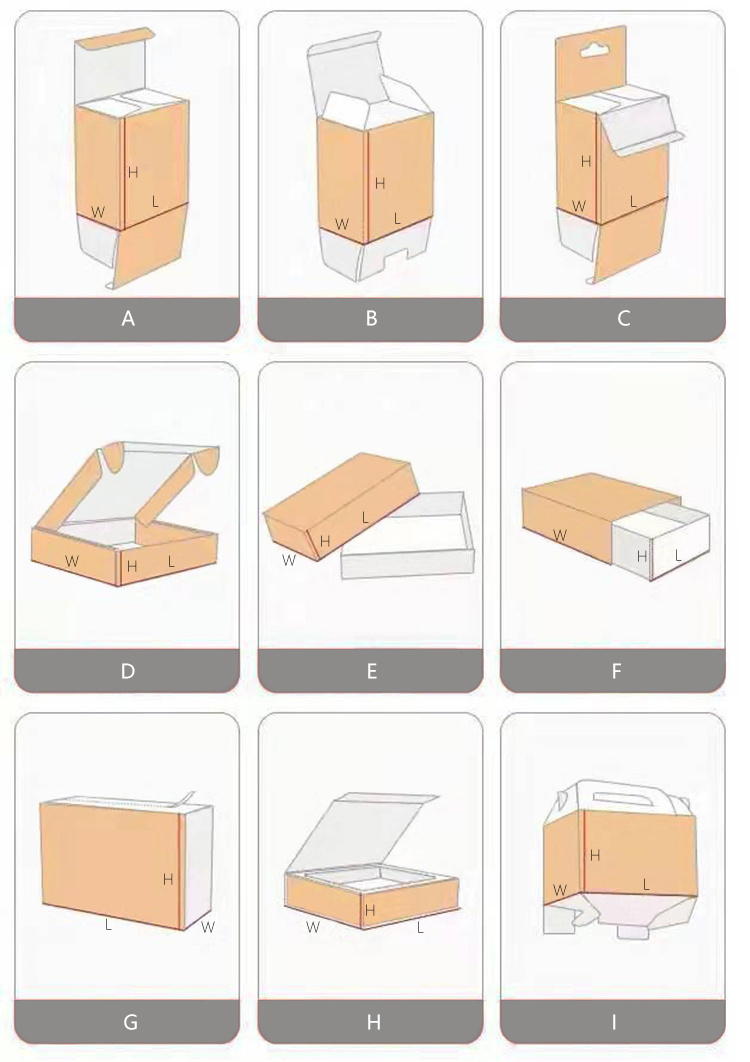

The box type as follow

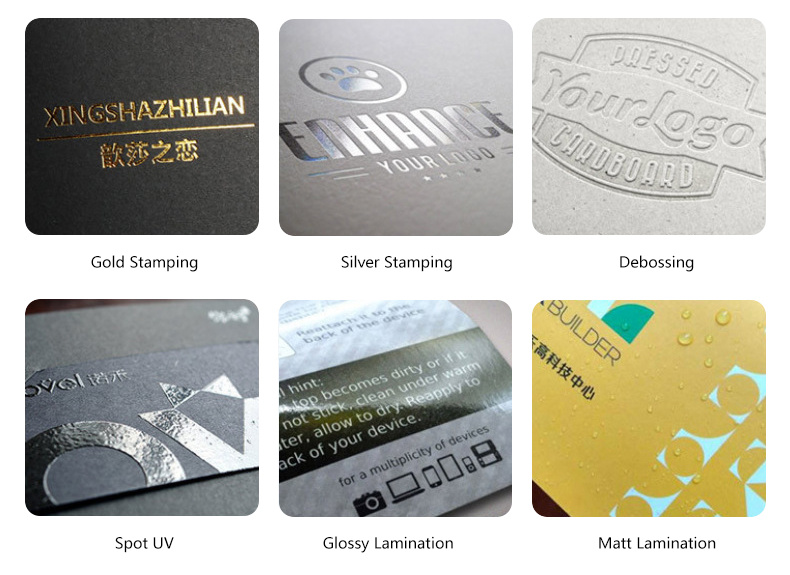

Surface treatment process

Foil Stamping

There are many kinds of foil stamping materials, including gold, silver, laser gold, laser silver, black, red, green, etc.

Lamination

Lamination process refers to using a film covering machine to cover the surface of printed matter with a layer of transparent plastic film.

Debossing

Concave and convex embossing is to use the greater pressure of the relief printing machine to roll the local patterns or characters on the printed semi-finished products into distinct concave and convex, three-dimensional images and characters.

Spot UV

Through UV drying and curing, the ink is bright and special, especially for trademarks, logos and local printing content.

Common Surface Treatment as Follows

Customer Question & Answer

Please contact customer service for more information.

Your response of following questions will help us recommend the most suitable package.

The packaging material consists of outer paper, medium paper and inner paper.

The outer paper is white board paper or white cardboard. After printing on the outer paper, it is pasted on the corrugated board by the auto-laminating machine.

Depending on the overall structure, corrugated paperboard can be split into 3 layers, 5 layers, and 7 layers.

Three parts can be as customized size and weight. Outside & inside paper can be printed OEM design and color.

Face paper material – coated duplex board

Face paper material – card paperboard.

Corrugated Cardboard Structure

Corrugated Cardboard Type

Packaging Applications

The box type as follow

Surface treatment process

Foil Stamping

There are many kinds of foil stamping materials, including gold, silver, laser gold, laser silver, black, red, green, etc.

Lamination

Lamination process refers to using a film covering machine to cover the surface of printed matter with a layer of transparent plastic film.

Debossing

Concave and convex embossing is to use the greater pressure of the relief printing machine to roll the local patterns or characters on the printed semi-finished products into distinct concave and convex, three-dimensional images and characters.

Spot UV

Through UV drying and curing, the ink is bright and special, especially for trademarks, logos and local printing content.

Common Surface Treatment as Follows