Ribbon Handle Kraft Cardboard Environmentally Degradable Paper Shoe Packaging Box with Window

Description

Flexo printing as design show more details of products, and no plastic lamination is much environmental.

The material is strong corrugated paperboard in 3 ply corrugated to fit different weight and size of gift product.

There are several kinds of rope, such as cotton rope, flap carton rope, ribbon, 3 standards twisted rope.

It can be used for shipping, gifts, logistics packaging.

Basic Info.

|

Product Name |

kraft Paper Shoe Box |

Surface Handling |

No lamination |

|

Box Style |

Portable kraft paper box |

Logo Printing |

Customized Logo |

|

Material Structure |

250 /300/350/400/500gsm kraft paper |

Origin |

Ningbo |

|

Materials Weight |

41 gram weight |

Sample |

Accept custom samples |

|

Shape |

Rectangle with handle |

Sample Time |

5-8 Working Days |

|

Color |

CMYK Color, Pantone Color |

Production Lead Time |

8-12 working days based on quantity |

|

Printing |

Offset Printing |

Transport Package |

Strong 5 ply Corrugated Carton |

|

Type |

Single Printing Box |

MOQ |

2000PCS |

Detailed Images

One delicate box bases on succeed every details. We have own professional team to check structure and printing. Die-cut design will adjust box with different materials. Please attach more details below.

Material Structure and Application

The thickness of kraft paper used for packaging box is 250gr, 280gr, 300gr, 350gr, 400gr and 450gr. Too thick kraft paper is not easy to fold.

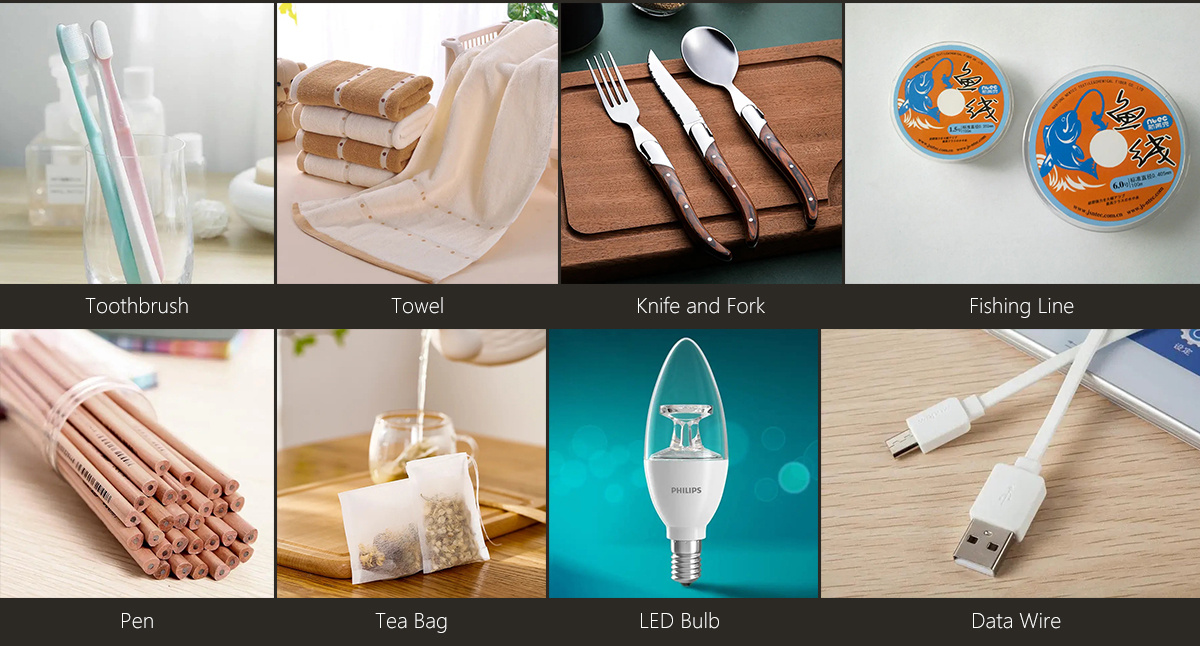

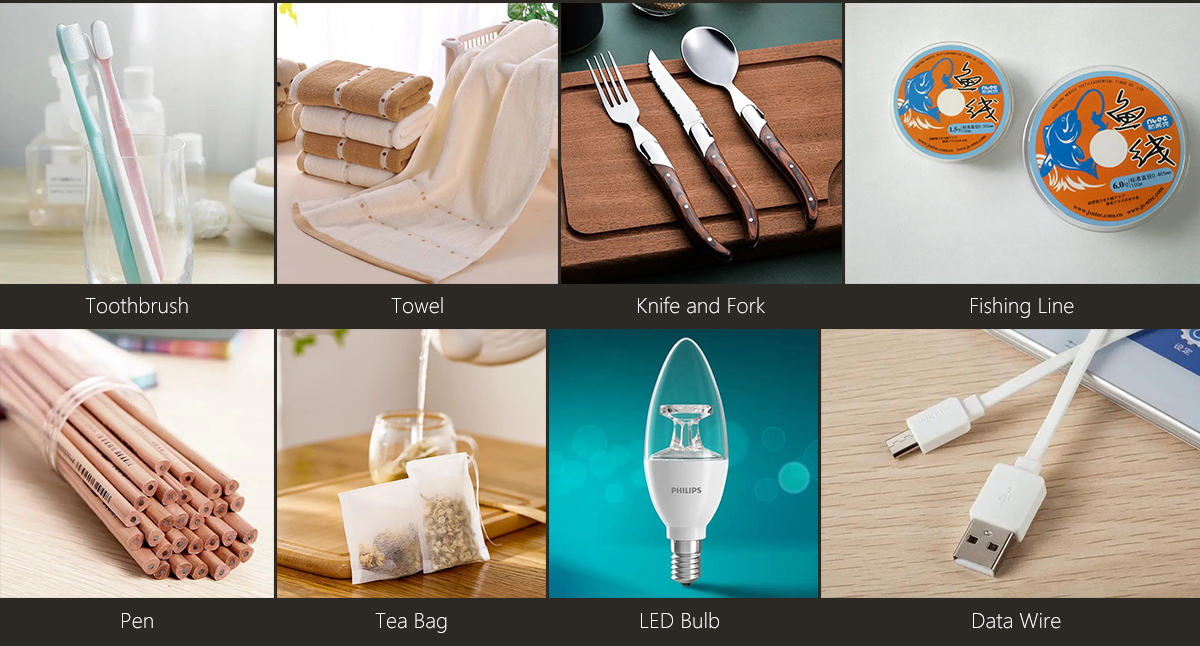

Packaging Applications

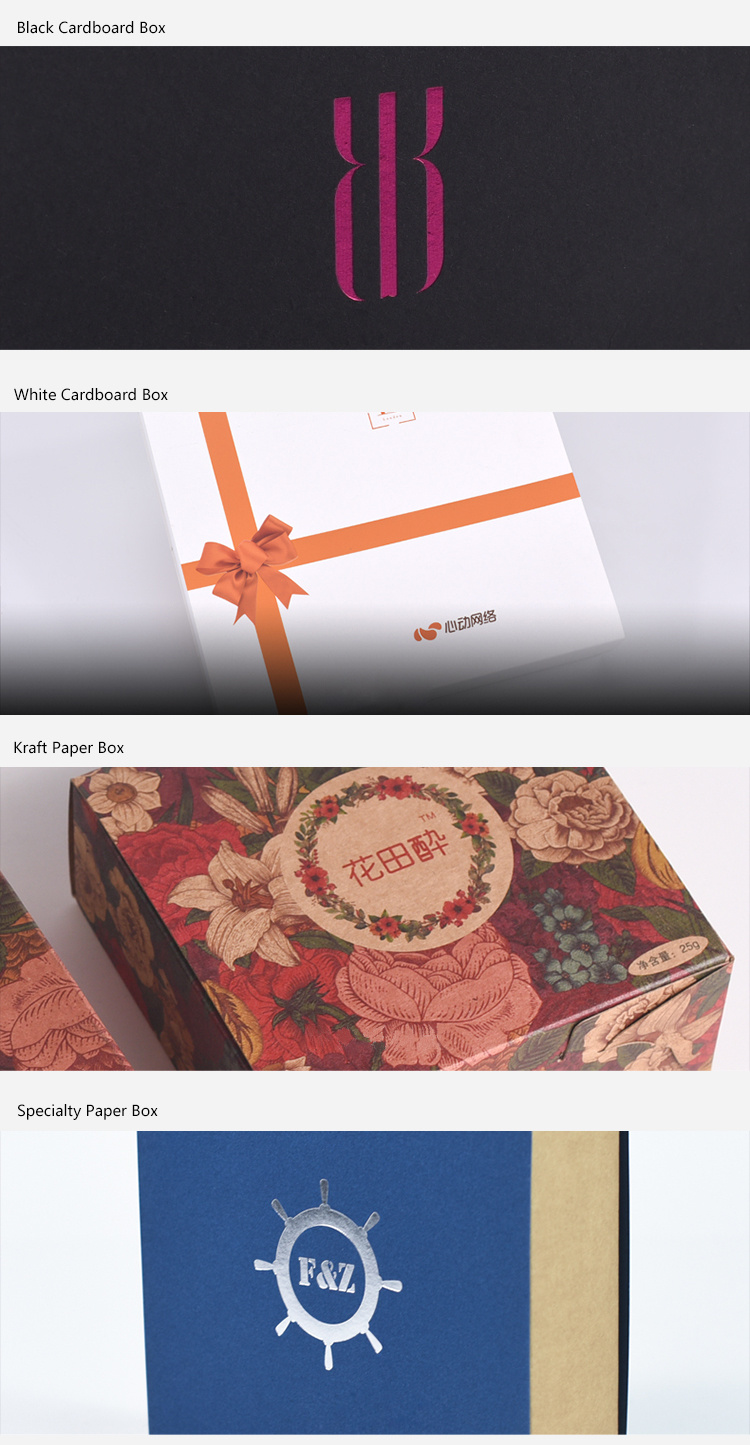

Box Type and Finish Surface

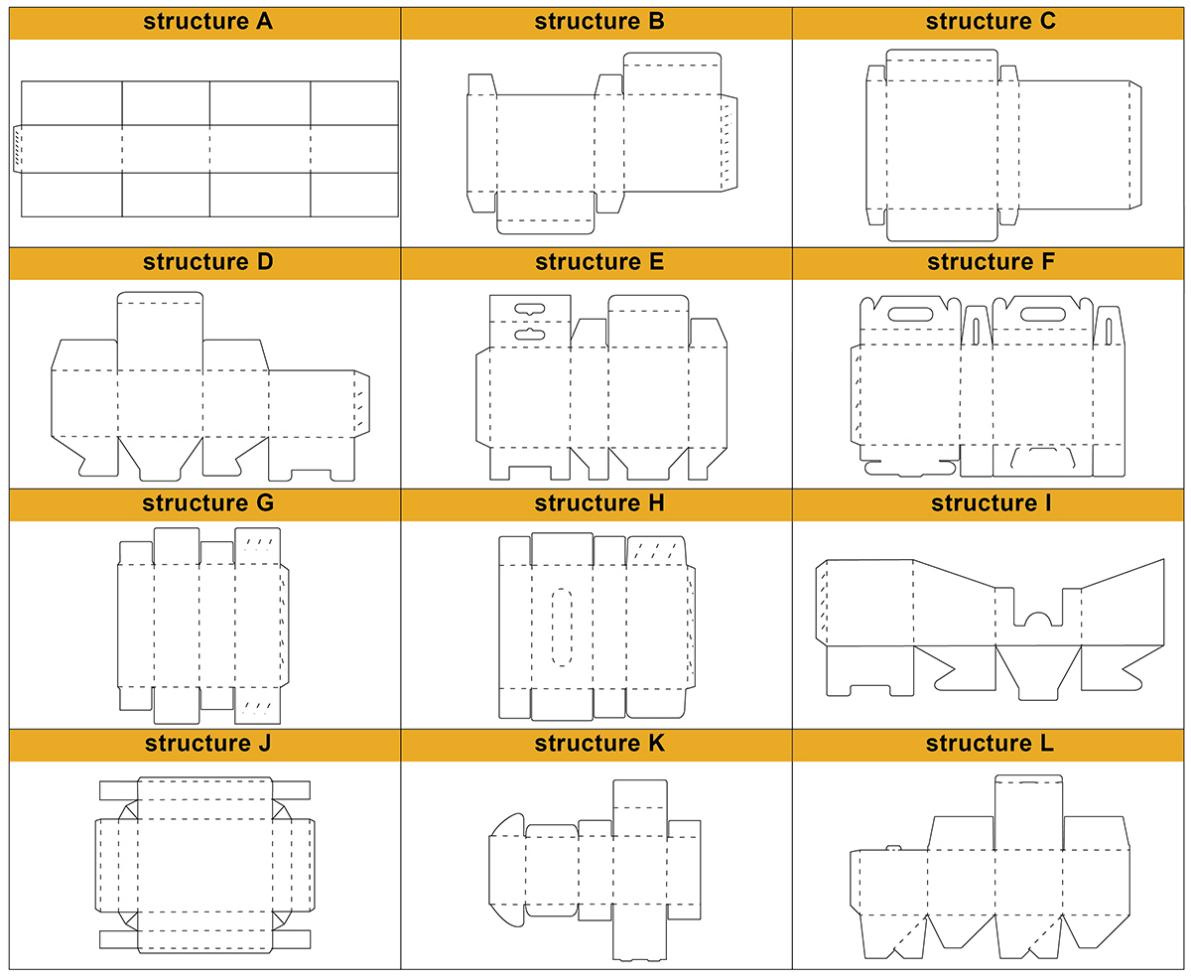

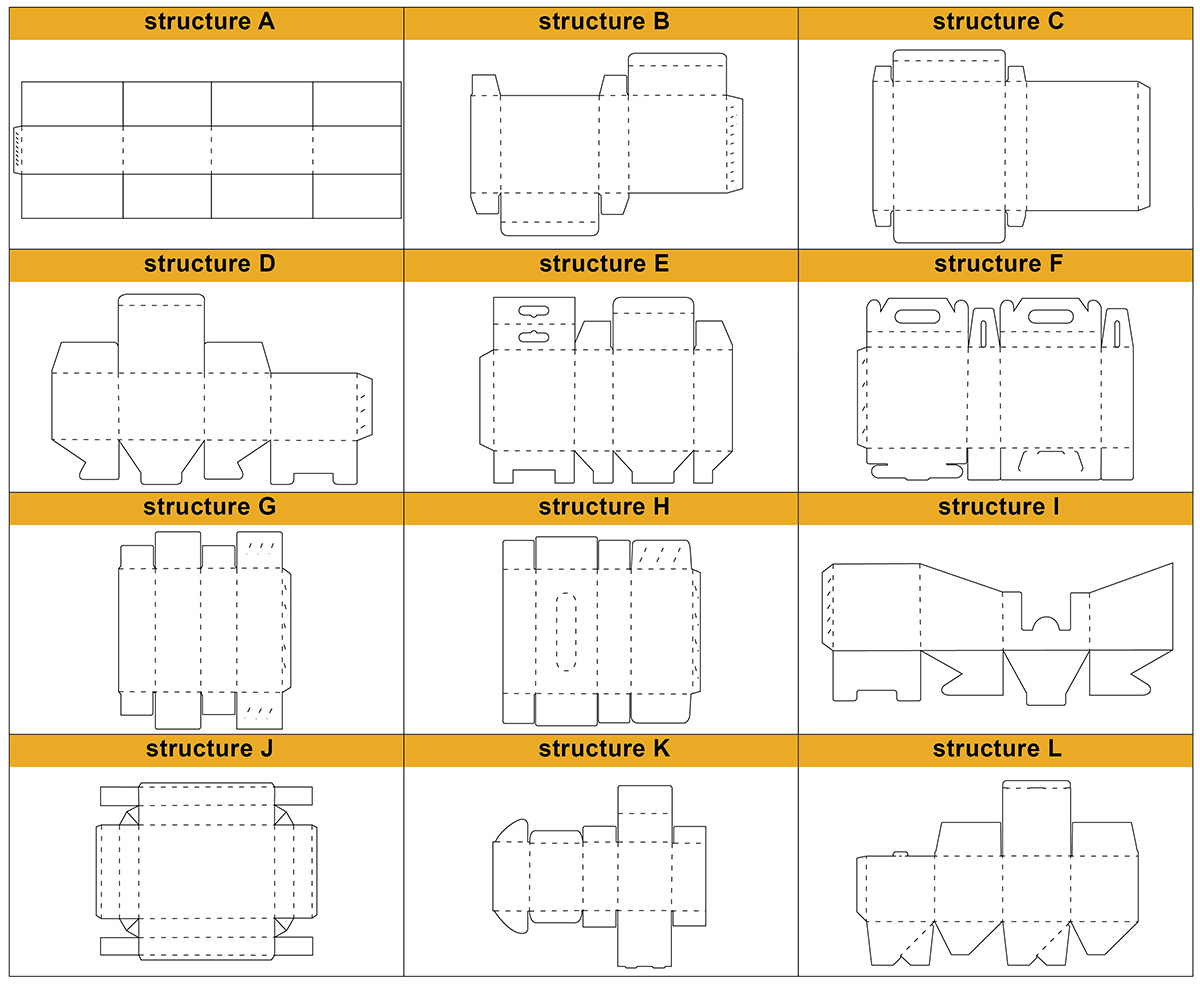

The box type as follow

The surface treatment process of printed products generally refers to the post-processing process of printed products, in order to make the printed products more durable, convenient for transportation and storage, and look more high-end, atmospheric and high-grade. Printing surface treatment includes: lamination, spot UV, gold stamping, silver stamping, concave convex, embossing, hollow-carved, laser technology, etc.

Common Surface Treatment as Follows

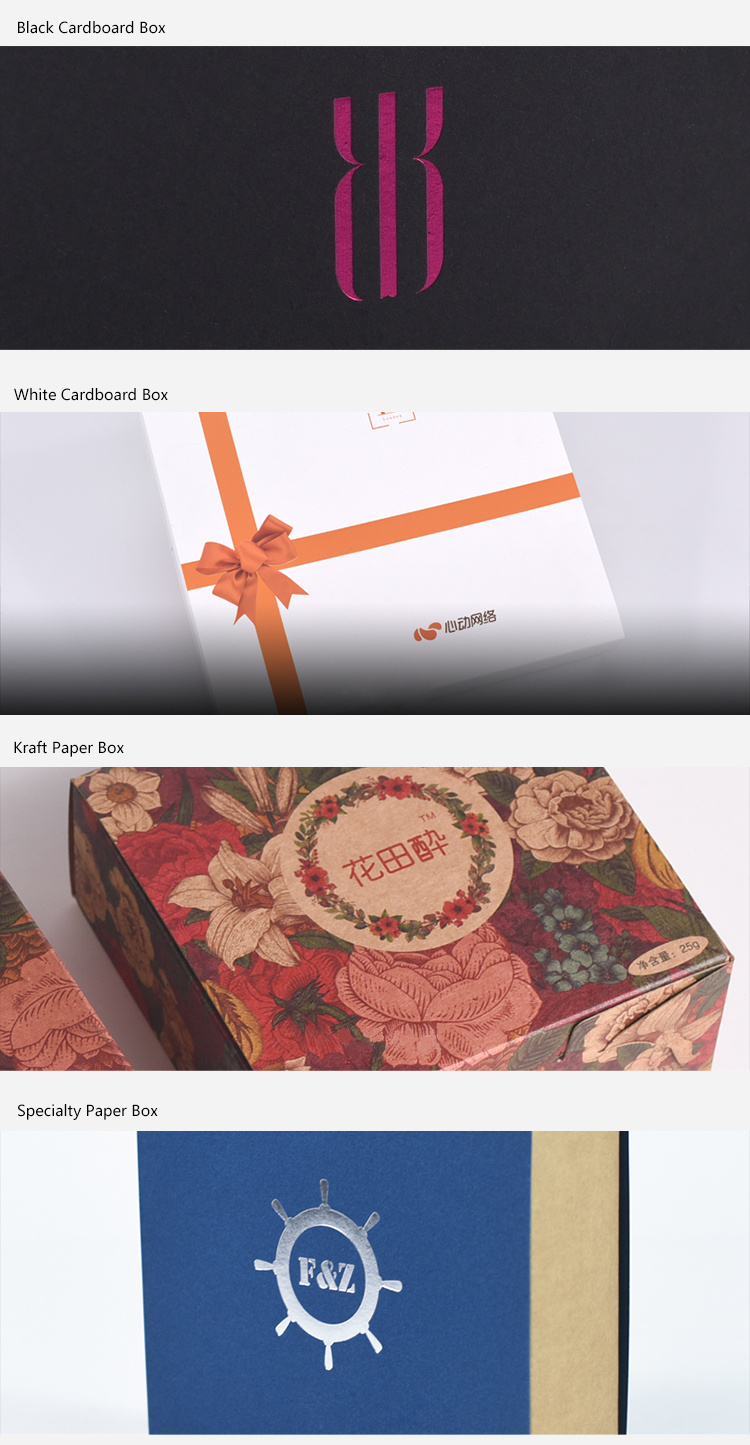

Card box printing effect comparison

White Card Paper

Both sides of the white card paper are white. The surface is smooth and flat, the texture is hard, thin and crisp, and can be used for double-sided printing. It has relatively uniform ink absorption and folding resistance.

Kraft Paper

Kraft paper is flexible and strong, with high breaking resistance. It can withstand large tension and pressure without cracking.

Black Card Paper

Black cardboard is colored cardboard. According to different colors, it can be divided into red card paper, green card paper, etc. Its biggest drawback is that it can not print color, but it can be used for bronzing and silver stamping. The most commonly used is white card.

Corrugated Paperboard

The advantages of corrugated paperboard are: good cushioning performance, light and firm, sufficient raw materials, low cost, convenient for automatic production, and low packaging cost. Its disadvantage is poor moisture-proof performance. Humid air or long-term rainy days will cause the paper to become soft and poor.

Coated Art Paper

Coated paper has smooth surface, high whiteness and good ink absorption performance. It is mainly used for printing advanced picture books, calendars and books, etc.

Specialty Paper

Special paper is made by special paper processing equipment and technology. The processed finished paper has rich colors and unique lines. It is mainly used for printing covers, decorations, handicrafts, hardcover gift boxes, etc.

Customer Question & Answer

Please contact customer service for more information.

Your response of following questions will help us recommend the most suitable package.

The thickness of kraft paper used for packaging box is 250gr, 280gr, 300gr, 350gr, 400gr and 450gr. Too thick kraft paper is not easy to fold.

Packaging Applications

The box type as follow

The surface treatment process of printed products generally refers to the post-processing process of printed products, in order to make the printed products more durable, convenient for transportation and storage, and look more high-end, atmospheric and high-grade. Printing surface treatment includes: lamination, spot UV, gold stamping, silver stamping, concave convex, embossing, hollow-carved, laser technology, etc.

Common Surface Treatment as Follows

Card box printing effect comparison

White Card Paper

Both sides of the white card paper are white. The surface is smooth and flat, the texture is hard, thin and crisp, and can be used for double-sided printing. It has relatively uniform ink absorption and folding resistance.

Kraft Paper

Kraft paper is flexible and strong, with high breaking resistance. It can withstand large tension and pressure without cracking.

Black Card Paper

Black cardboard is colored cardboard. According to different colors, it can be divided into red card paper, green card paper, etc. Its biggest drawback is that it can not print color, but it can be used for bronzing and silver stamping. The most commonly used is white card.

Corrugated Paperboard

The advantages of corrugated paperboard are: good cushioning performance, light and firm, sufficient raw materials, low cost, convenient for automatic production, and low packaging cost. Its disadvantage is poor moisture-proof performance. Humid air or long-term rainy days will cause the paper to become soft and poor.

Coated Art Paper

Coated paper has smooth surface, high whiteness and good ink absorption performance. It is mainly used for printing advanced picture books, calendars and books, etc.

Specialty Paper

Special paper is made by special paper processing equipment and technology. The processed finished paper has rich colors and unique lines. It is mainly used for printing covers, decorations, handicrafts, hardcover gift boxes, etc.