RETF Printed Corrugated Packing Mailer Box with Paper Insert

Description

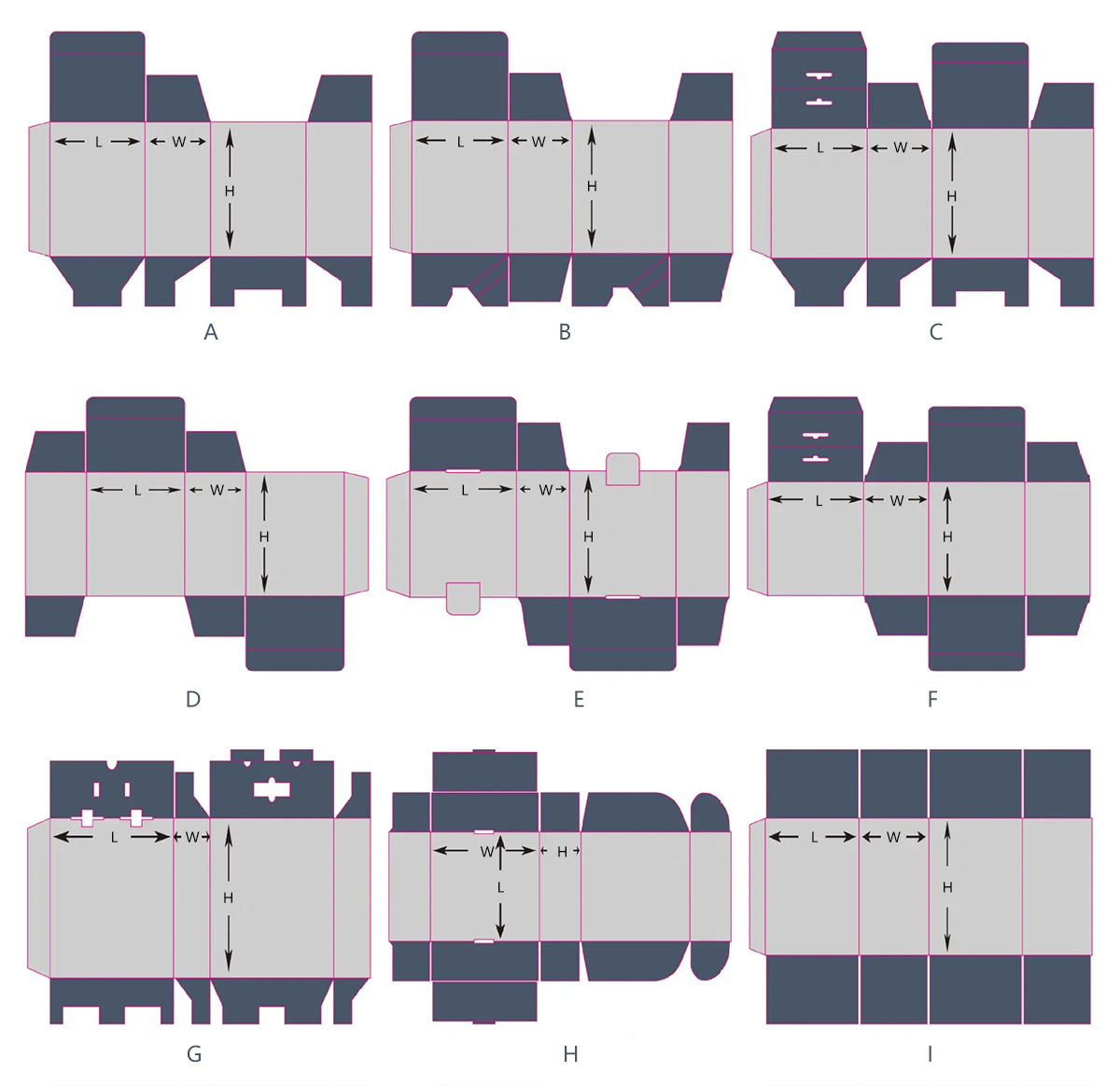

• Structure K , Roll-end tuck-front with dust flaps boxes

It is popular structure in paper packing carton, for its flat pieces and strong structure .

Basic Info.

|

Product Name |

Color Corrugated Box |

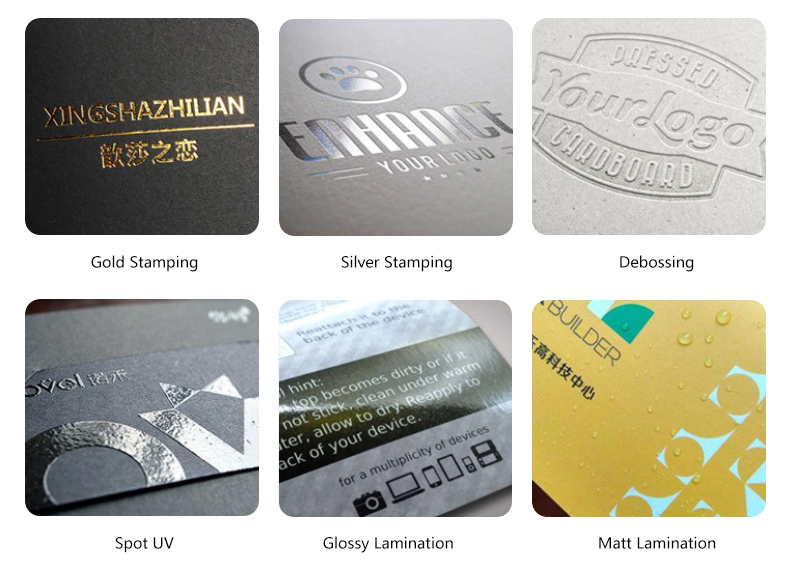

Surface Handling |

Gold Stamping, Matt Lamination |

|

Box Style |

Folding Corrugated Box |

Logo Printing |

OEM |

|

Material Structure |

White Board + Corrugated Paper + White Board |

Origin |

Ningbo,Shanghai port |

|

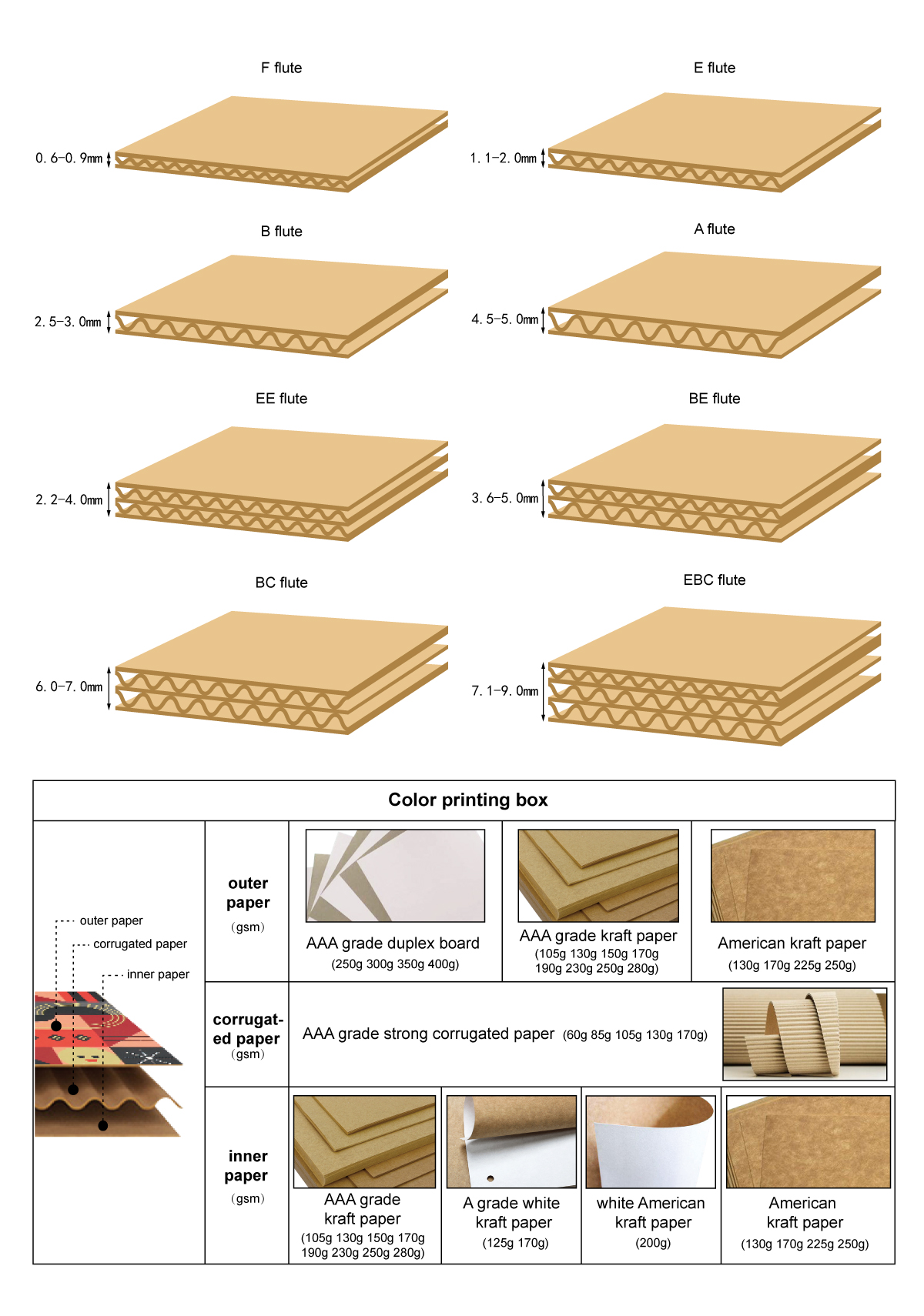

Flute Type |

E Flute, B Flute, C Flute, BE Flute |

Sample |

Accept |

|

Shape |

Rectangle |

Sample Time |

5-7 Working Days |

|

Color |

CMYK Color, Pantone Color |

Business term |

FOB, CIF |

|

Printing |

Offset Printing, Flexo Printing |

Transport Package |

By carton, bundle, pallets |

|

Type |

Single side Printing Box |

Shipping |

By sea, air, express |

Detailed Images

To a large extent, carton packaging is based on its exquisite shape and decoration to promote the beautification of goods and improve the competitiveness of goods. Because the shape and structure design of the carton is often determined by the shape characteristics of the packaged goods, so its style and type are many, there are rectangular, square, multilateral, special carton, cylindrical, etc., but the manufacturing process is basically the same, that is, the selection of materials - design ICONS - manufacturing templates - stamping - synthetic box.

Material Structure and Application

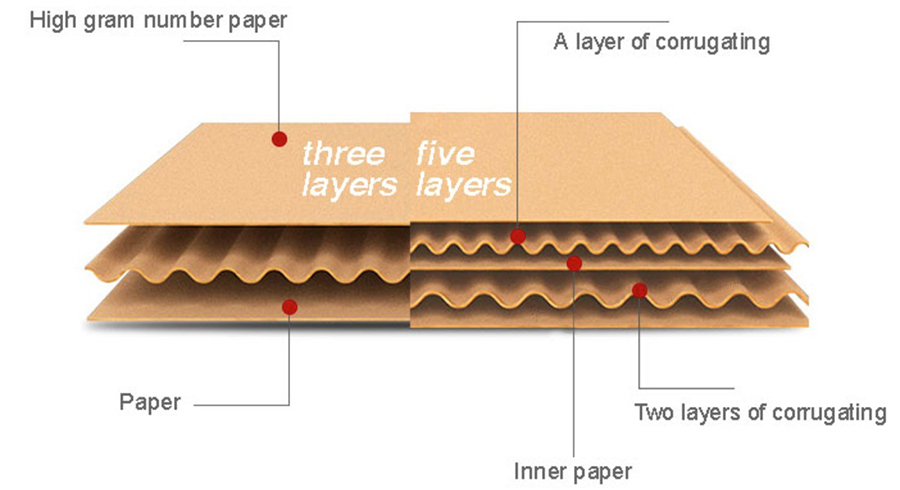

♦ Corrugated paperboard

Corrugated paper is made of hanging paper and corrugated paper formed by corrugated roller processing and bonding board.

generally divided into single corrugated board and double corrugated board two categories, according to the size of corrugated is divided into: A, B, C, E, F five types.

♦ Corrugated classification

♦ Using application

Corrugated board first began in the late 18th century. In the 19th century, people found that corrugated board is not only light, strong performance, the price is cheaper than the general material, and the production process is simple, more widely used. Moreover, corrugated cardboard is not only a recyclable and environmentally friendly material composed of wood fibers that can be decomposed by natural action, but also can be reused without affecting its performance.

Box Type and Finish Surface

♦ Carton , Hard paper case

Carton is the most widely used packaging products. According to different materials, there are corrugated cartons, single-layer cardboard boxes, etc., with various specifications and models.

Carton structure can be customized according to customer requirements. Common structures are: cover type structure, shake type structure, window type structure, drawer type structure, carrying type structure, display type structure, closed structure, heterogeneous structure and so on.

♦ Surface Treatment

• Glossy lamination , Matte lamination

Laminating is the plastic film coated with adhesive, and the paper as substrate printed matter, after the rubber roller and heating roller pressure together, forming a paper-plastic product. Covered with matte film, is in the name card surface covered with a layer of frosted texture film; Coating film, is a layer of glossy film on the surface of the business card. The coated products, due to its surface more than a layer of thin and transparent plastic film, smooth and bright surface, graphic color more bright, at the same time play the role of waterproof, anti-corrosion, wear resistance, dirty resistance and so on.