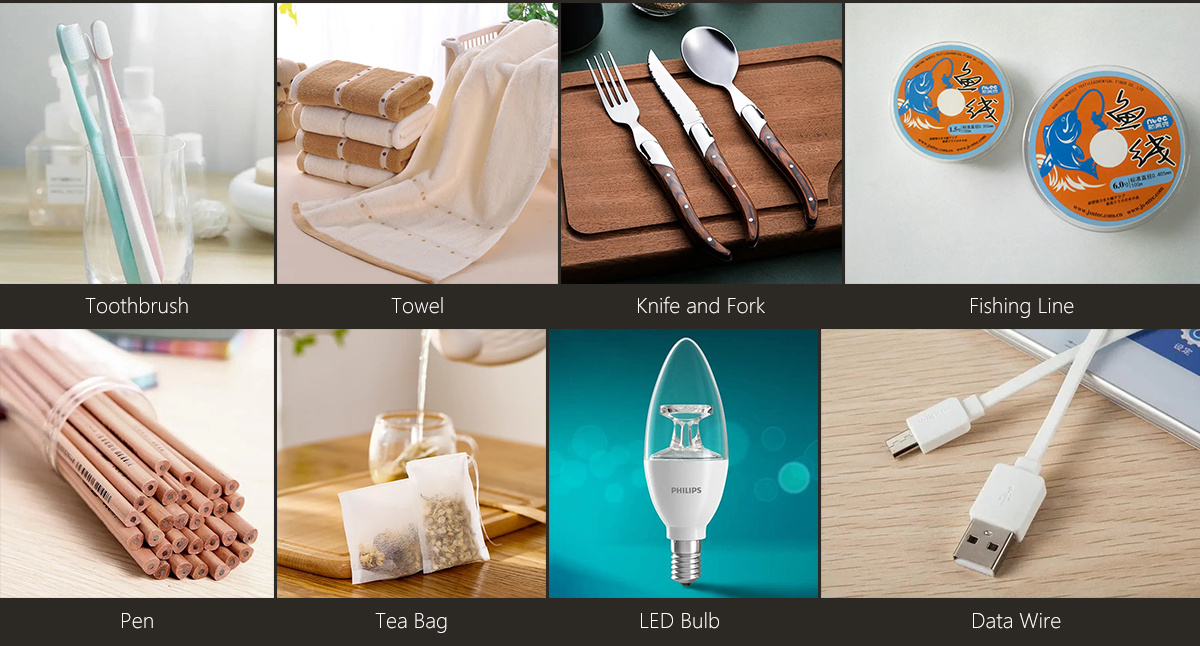

China Cheap Manufacturer OEM Logo Recyclable 400 Gram Food Grade Luxury Printing Self-forming Bottom Paper Box for Coffee Tea

Description

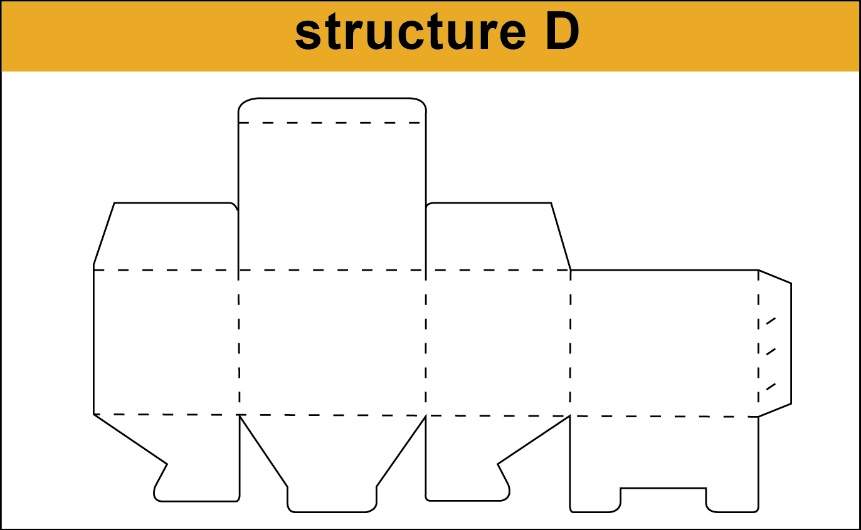

Structure : D structure

Printing:UV printing on white kraft paper, without plastic lamination. This is printing technology is 100% bio-degradable of boxes.

Package: use 5 layers corrugated carton box.

Shipping: by sea/air, express, etc.

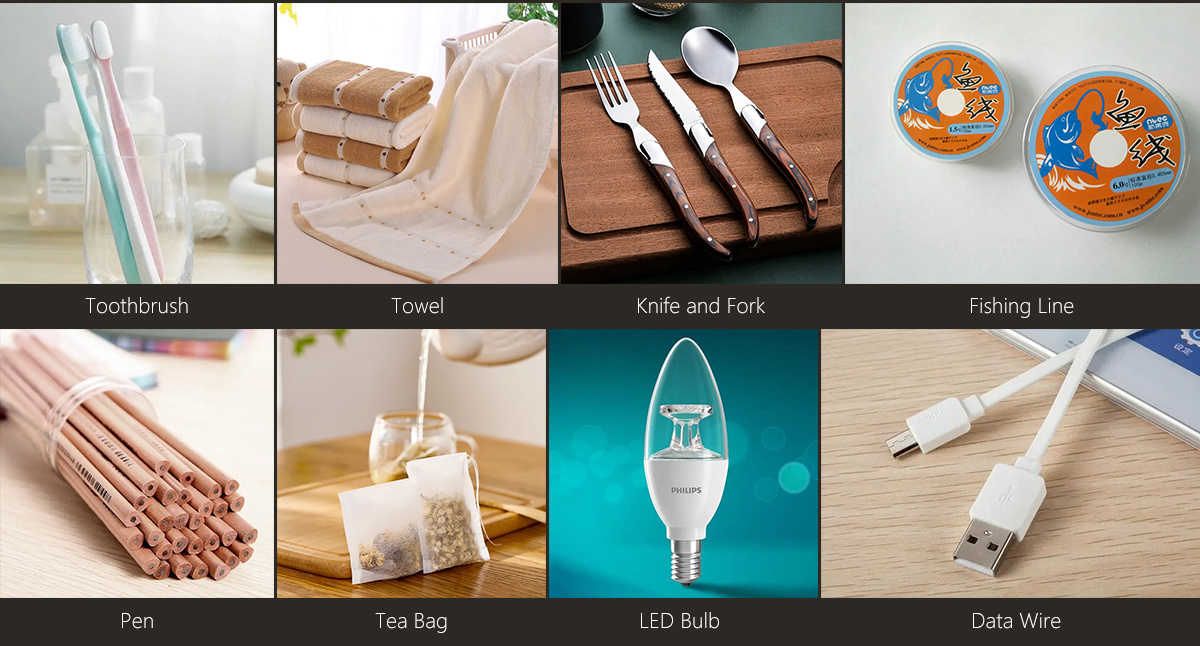

Usage: Color paper box package coffee, tea, cookies and so on.

Basic Info

| Product Name | White Card Coffee Box | Surface Finish | No lamination |

| Box Style | Self-forming Bottom | Logo Printing | oem |

| Material type | 250 /300/350/400gram ivory board | Origin | Ningbo, China |

| Shining point | Opening by tear line | Sample | accept |

| Shape | Rectangle,customized | Sample Time | 5-7 Working Days |

| Color | CMYK Color, Pantone Color | Port | Shanghai/Ningbo port |

| Printing | UV printing | Transport Package | Strong 5 ply Corrugated Carton |

| Type | Single /Two-sided Printing Box | Business term | FOB,CIF, DDU etc. |

Detailed Images

We have own professional team on product department , design department, samples department,inspection department and after service.

Design department: Free offer die line file in different structure and materials after order.

Product department: Self checking and after each process and summarize feedback in time.

After service: Service not finish after shipping. We are always on line.

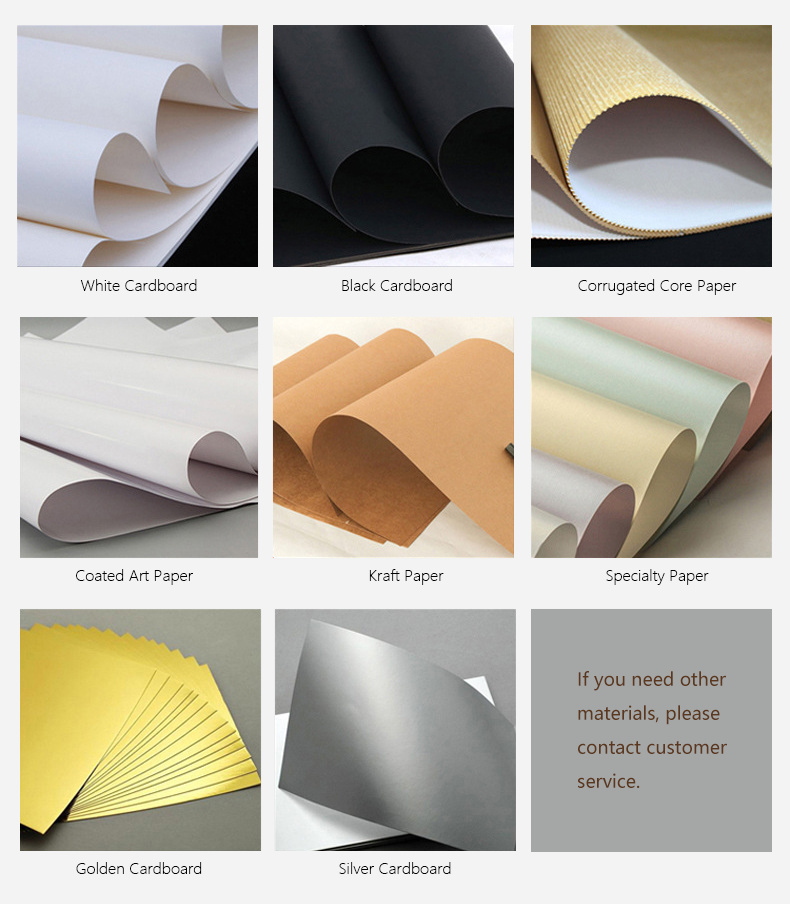

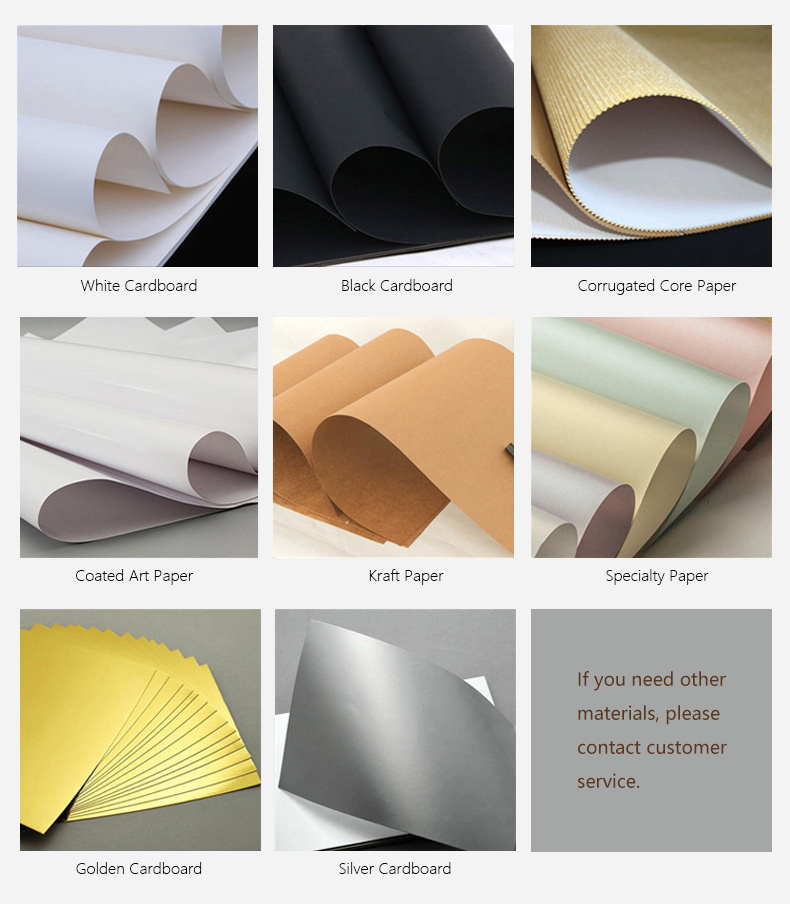

Material Structure and Application

Degradable paper package materials are much popular. It can be with luxury printing as OEM LOGO design as gift and shipping box. Environmental materials are standard requirements in most countries. Please attach follow environmental paper materials.

Usual paper kind

White Card Paper

Both sides of the white card paper are white. The surface is smooth and flat, the texture is hard, thin and crisp, and can be used for double-sided printing. It has relatively uniform ink absorption and folding resistance.

Black Card Paper

Black cardboard is colored cardboard. According to different colors, it can be divided into red card paper, green card paper, etc. Its biggest drawback is that it can not print color, but it can be used for bronzing and silver stamping. The most commonly used is white card.

Corrugated Paperboard

The advantages of corrugated paperboard are: good cushioning performance, light and firm, sufficient raw materials, low cost, convenient for automatic production, and low packaging cost. Its disadvantage is poor moisture-proof performance. Humid air or long-term rainy days will cause the paper to become soft and poor.

Corrugated Paperboard

The advantages of corrugated paperboard are: good cushioning performance, light and firm, sufficient raw materials, low cost, convenient for automatic production, and low packaging cost. Its disadvantage is poor moisture-proof performance. Humid air or long-term rainy days will cause the paper to become soft and poor.

Coated Art Paper

Coated paper has smooth surface, high whiteness and good ink absorption performance. It is mainly used for printing advanced picture books, calendars and books, etc.

Kraft Paper

Kraft paper is flexible and strong, with high breaking resistance. It can withstand large tension and pressure without cracking.

Specialty Paper

Special paper is made by special paper processing equipment and technology. The processed finished paper has rich colors and unique lines. It is mainly used for printing covers, decorations, handicrafts, hardcover gift boxes, etc.

Application

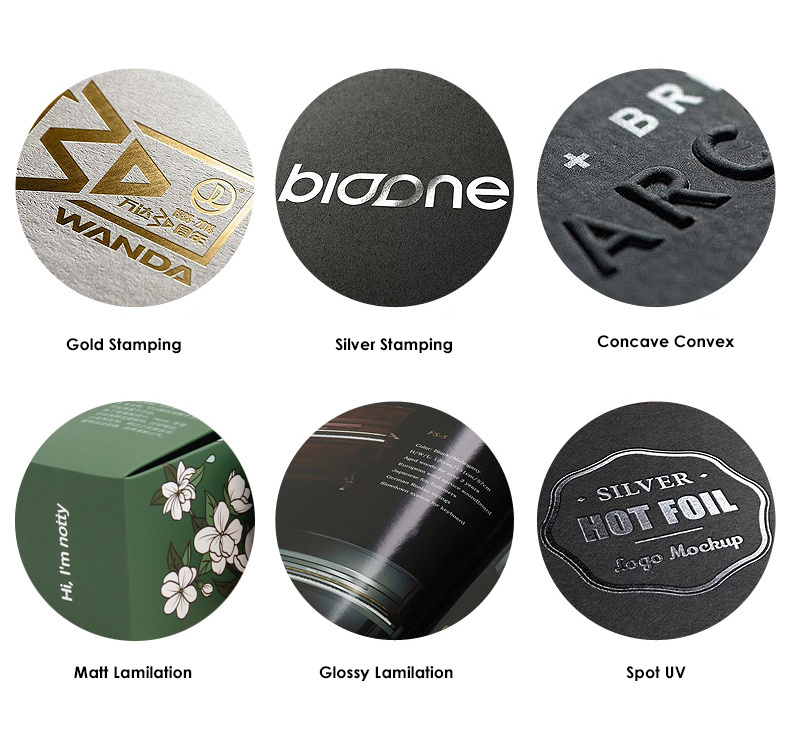

Box Type and Finish Surface

Sample boxes

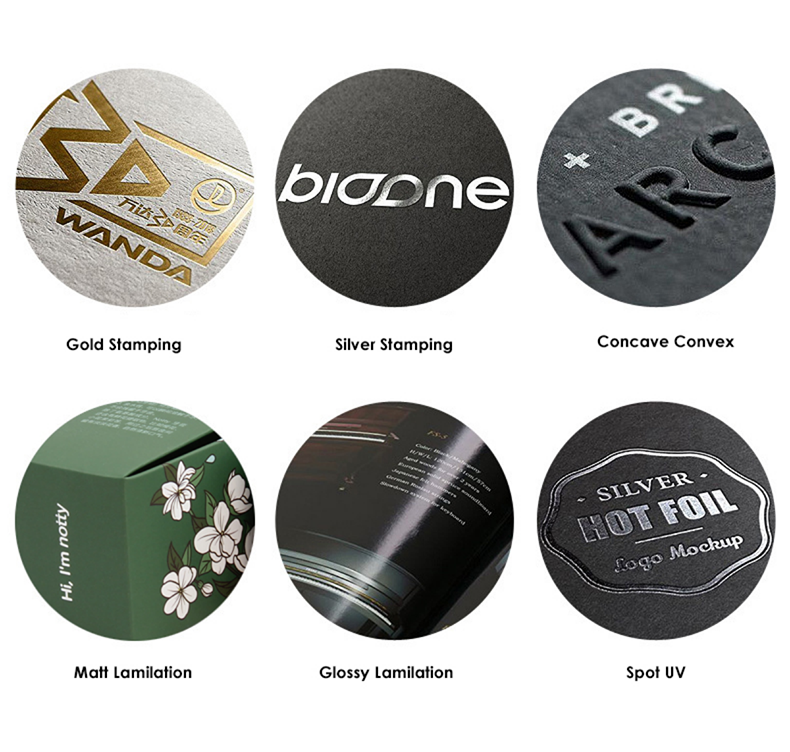

Surface Treatment

The common main junction surface treatment is the process of forming a layer on the surface of the matrix material which is different from the mechanical, physical and chemical properties of the matrix. The purpose of surface treatment is to meet the corrosion resistance, wear resistance, decoration or other special functional requirements of the product. For metal castings, we are more commonly used surface treatment method is mechanical grinding, chemical treatment, surface heat treatment, spraying surface, surface treatment is to clean the workpiece surface, cleaning, deburring, oil, oxidation and so on.

Common Surface Treatment as Follows

Customer Question & Answer

Please contact customer service for more information.

Your response of following questions will help us recommend the most suitable package.

Degradable paper package materials are much popular. It can be with luxury printing as OEM LOGO design as gift and shipping box. Environmental materials are standard requirements in most countries. Please attach follow environmental paper materials.

Usual paper kind

White Card Paper

Both sides of the white card paper are white. The surface is smooth and flat, the texture is hard, thin and crisp, and can be used for double-sided printing. It has relatively uniform ink absorption and folding resistance.

Black Card Paper

Black cardboard is colored cardboard. According to different colors, it can be divided into red card paper, green card paper, etc. Its biggest drawback is that it can not print color, but it can be used for bronzing and silver stamping. The most commonly used is white card.

Corrugated Paperboard

The advantages of corrugated paperboard are: good cushioning performance, light and firm, sufficient raw materials, low cost, convenient for automatic production, and low packaging cost. Its disadvantage is poor moisture-proof performance. Humid air or long-term rainy days will cause the paper to become soft and poor.

Corrugated Paperboard

The advantages of corrugated paperboard are: good cushioning performance, light and firm, sufficient raw materials, low cost, convenient for automatic production, and low packaging cost. Its disadvantage is poor moisture-proof performance. Humid air or long-term rainy days will cause the paper to become soft and poor.

Coated Art Paper

Coated paper has smooth surface, high whiteness and good ink absorption performance. It is mainly used for printing advanced picture books, calendars and books, etc.

Kraft Paper

Kraft paper is flexible and strong, with high breaking resistance. It can withstand large tension and pressure without cracking.

Specialty Paper

Special paper is made by special paper processing equipment and technology. The processed finished paper has rich colors and unique lines. It is mainly used for printing covers, decorations, handicrafts, hardcover gift boxes, etc.

Sample boxes

Surface Treatment

The common main junction surface treatment is the process of forming a layer on the surface of the matrix material which is different from the mechanical, physical and chemical properties of the matrix. The purpose of surface treatment is to meet the corrosion resistance, wear resistance, decoration or other special functional requirements of the product. For metal castings, we are more commonly used surface treatment method is mechanical grinding, chemical treatment, surface heat treatment, spraying surface, surface treatment is to clean the workpiece surface, cleaning, deburring, oil, oxidation and so on.

Common Surface Treatment as Follows