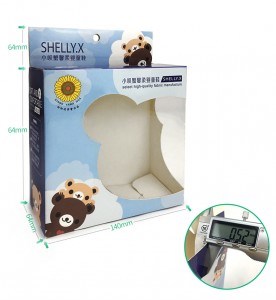

Recyclable Printed Paper Package Baby Box with Window Paper Handle

Description

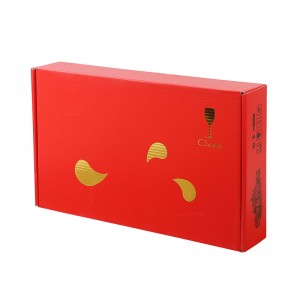

To a large extent, carton packaging is based on its exquisite shape and decoration to promote the beautification of goods and improve the competitiveness of goods. Because the shape and structure design of the carton is often determined by the shape characteristics of the packaged goods, so its style and type are many, there are rectangular, square, multilateral, special carton, cylindrical, etc., but the manufacturing process is basically the same, that is, the selection of materials - design ICONS - manufacturing templates - stamping - synthetic box.

Basic Info.

|

Product Name |

Baby Shoe Box with Window |

Surface Handling |

Matt Lamination, glossy lamination |

|

Box Style |

Paper Card Box with Paper Handle |

Logo Printing |

Customized Logo |

|

Material Structure |

High grade white paper board |

Origin |

Ningbo, shanghai port |

|

Material Weight |

400gram weight |

Sample |

Accept custom samples |

|

Shape |

Rectangle |

Sample Time |

5-8 Working Days |

|

Color |

CMYK Color, Pantone Color |

Production Lead Time |

8-12 working days based on quantity |

|

Printing |

Offset Printing |

Transport Package |

Strong 5 ply Corrugated Carton |

|

Type |

Single Printing Box |

Business term |

FOB, CIF |

Detailed Images

Carton is a three-dimensional shape, it is composed of a number of planes moving, stacking, folding, surrounded by a multi-faceted shape. The surface in three-dimensional construction plays the role of dividing space in space. The surface of different parts is cut, rotated and folded, and the surface obtained has different emotions. The composition of the carton display surface should pay attention to the connection between the display surface, side, top and bottom, and the setting of the packaging information elements.

Material Structure and Application

♦ Materials

• White card paper

White card paper is better, the price is a little expensive, but the texture and hardness are enough, again the point is white (white board).

• Powder board paper

Powder board paper: white on one side, grey on the other, lower price.

♦ Using application

Carton is a three-dimensional shape, it is composed of a number of planes moving, stacking, folding, surrounded by a multi-faceted shape. The surface in three-dimensional construction plays the role of dividing space in space. The surface of different parts is cut, rotated and folded, and the surface obtained has different emotions. The composition of the carton display surface should pay attention to the connection between the display surface, side, top and bottom, and the setting of the packaging information elements.

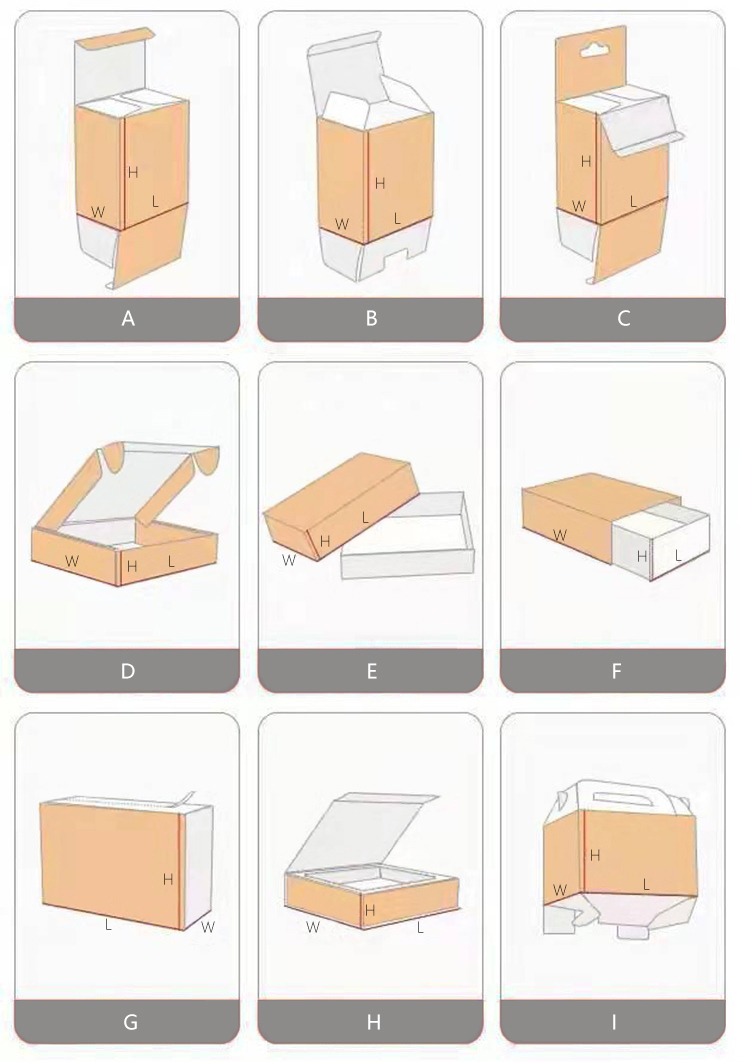

Box Type and Finish Surface

♦ Variety of box designs

Carton (hard paper case) : Carton is the most widely used packaging products.

According to different materials, there are corrugated cartons, single-layer cardboard boxes, etc., with various specifications and models.

Carton commonly has three layers, five layers, seven layers are less used, each layer is divided into inner paper, corrugated paper, core paper, face paper。 inner & face paper to be brown board paper, kraft paper, core paper with corrugated paper, all kinds of paper color and feel are different, different manufacturers of paper (color, feel) are different.

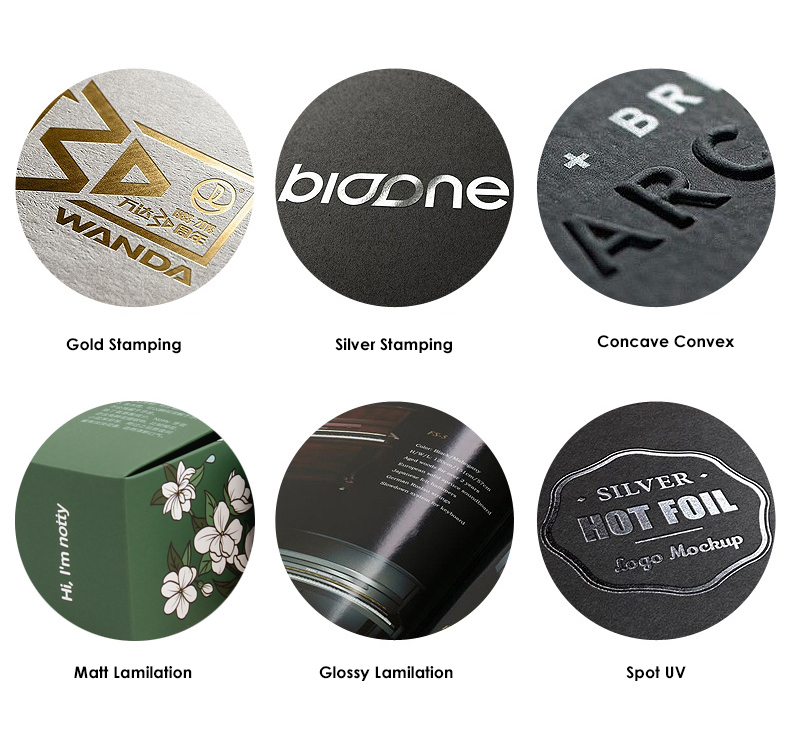

♦ Surface Disposal

Waterproof effect. The paper box in the warehouse storage, water is easy to mold, rot. After light oil and finish, it is equivalent to forming a protective film on the surface paper. Which can isolate the water vapor outside and protect the product.

Common Surface Treatment As Follows

• Spot UV

Local UV can be implemented after the film, also can be directly glazing on the print, but in order to highlight the effect of local glazing. Generally after the printing film, and to cover matte film, about 80% of the local UV glazing products.