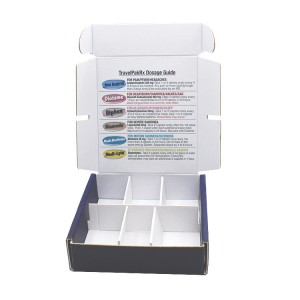

Blue Tuck Front Paper Box with white corrugated divider

Description

Structure: Roll-end tuck-front with dust flaps boxes (RETF)

Advantage points: 1) Outside blue inside white with introduction text;

2)Bio-degradable materials;

3) white divider in 4 /6

Samples: accept,

free for no printed sample;

Digital printing sample and bulk printing sample.

Lead time: 1-50000pcs, 7-14 working days after confirmed file.

≥50000pcs, to be negotiated

Basic Info.

| Product Name | REFT box with paper divider | Surface Handling | Glossy Lamination, Matt Lamination |

| Box Style | Folding Box | Logo Printing | oem |

| Material Structure | White Board + Corrugated Paper + White Kraft | Origin | Ningbo,China. |

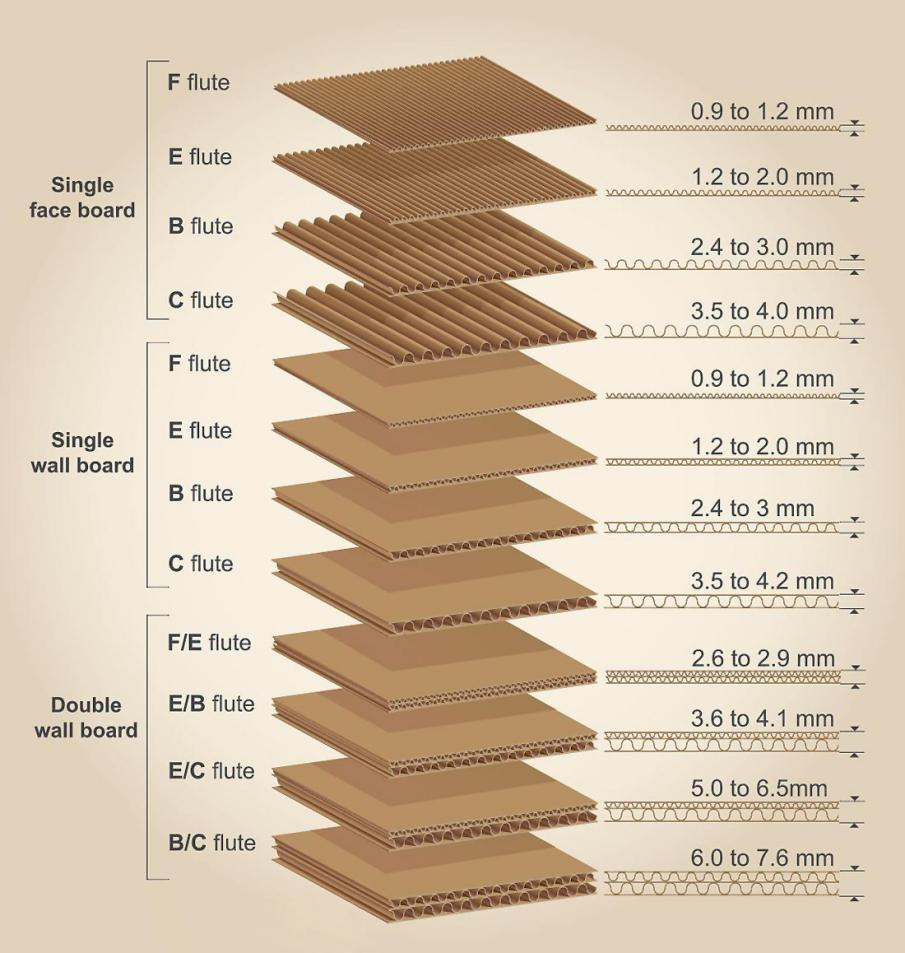

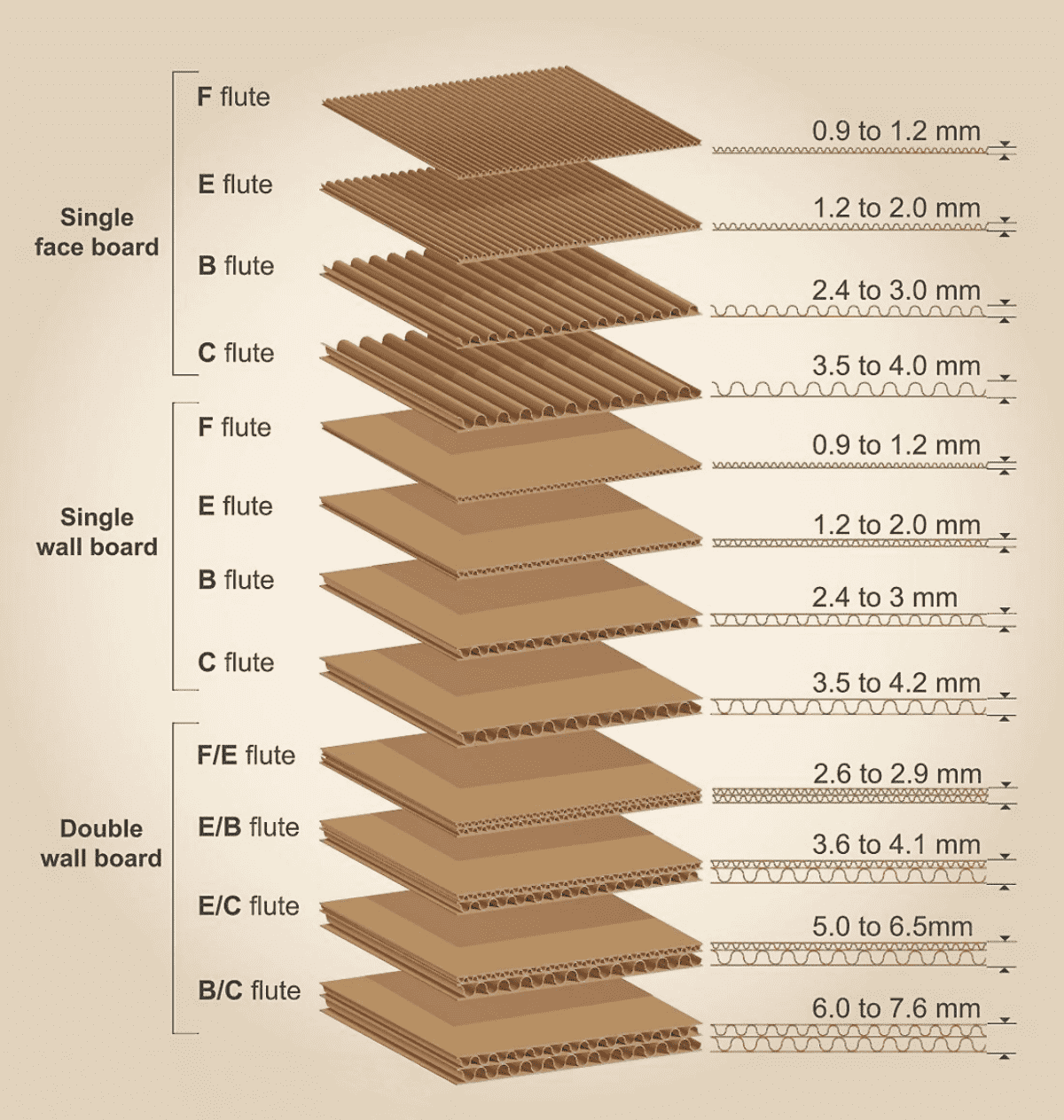

| Flute Type | E Flute, B Flute, C Flute, BE Flute | Thickness | 2mm, 3mm, 4mm, 5mm |

| Shape | Rectangle | Sample Time | 5-7 Working Days |

| Color | CMYK Color, Pantone Color | MOQ | 2000 pcs |

| Printing | Offset Printing | Transport Package | Strong 5 ply Corrugated Carton |

| Artwork | AI, CAD,PSD, etc. | Business term | EXW,FOB, CIF, DDU etc. |

Detailed Images

Certainly, here are some additional details about our services:

Product department - We have a strict quality control system in place, which means that every product undergoes thorough inspection at every stage of production. Our team is trained to spot any defects or flaws and take corrective action immediately.

Design department - We work closely with our clients to create unique and customized designs that cater to their specific needs. Our team is proficient in various design software and can provide clients with die line files in different structures and materials.

Samples department - We provide samples to clients before starting production to ensure that the final product meets their requirements. This allows us to make any necessary adjustments before mass production.

Inspection department - We conduct rigorous quality checks before shipping products to ensure that they meet our high standards.

After service - We understand that customer support is crucial, and we make sure to be available to our clients even after the products have been shipped. Our team is always on standby to address any concerns or issues that arise.

Overall, our goal is to provide our clients with a stress-free experience and high-quality products that meet their expectations.

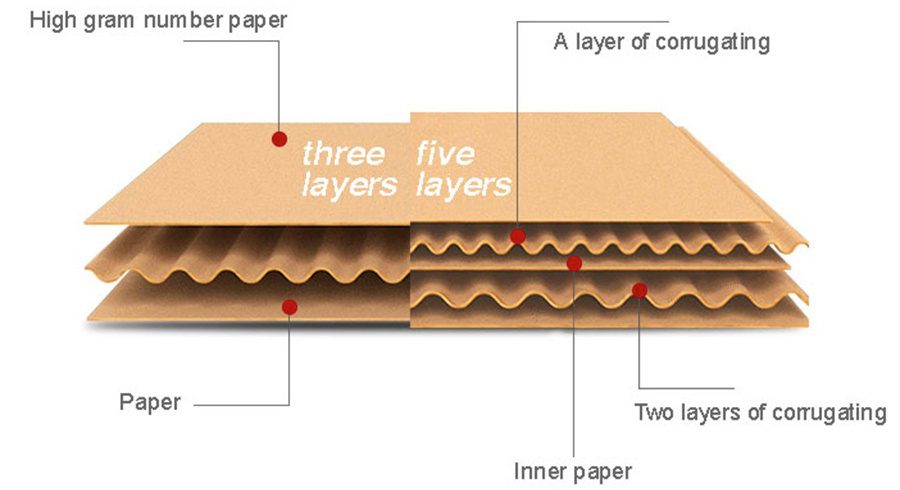

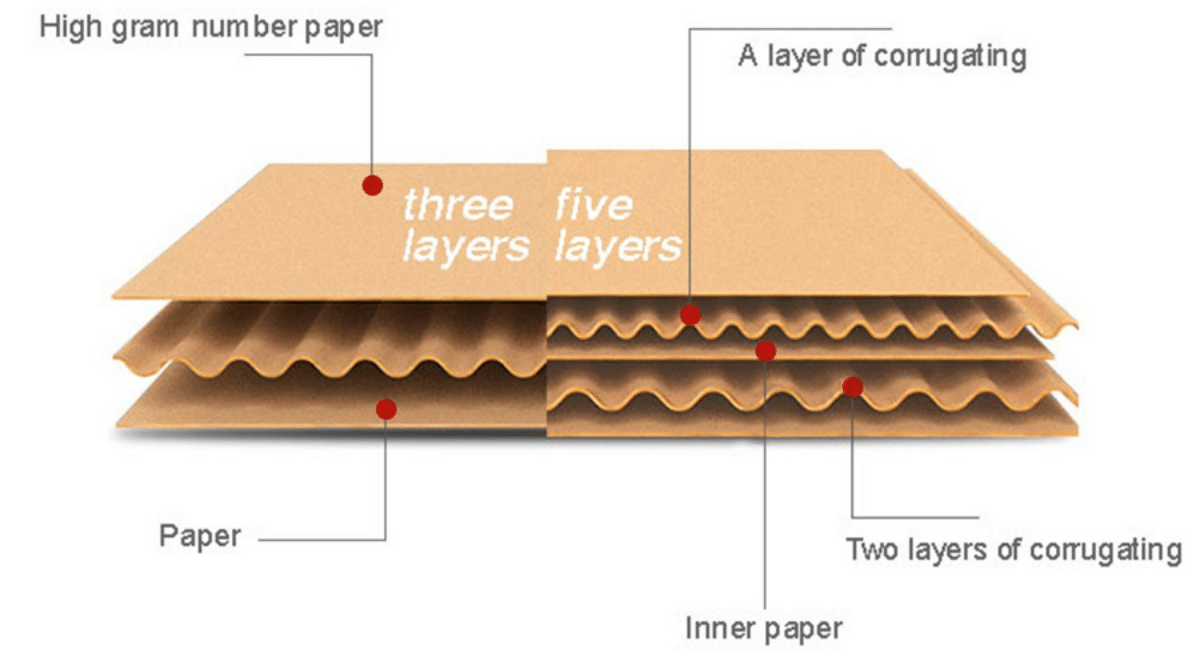

Material Structure and Application

Feature: Bio-degradable paper and corrugated cardboard.

Composition: brown paper/ white paper + different layer corrugated board+ brown /white paper

Common corrugated board: single wall --3 ply--F flute, E flute, B flute, C flute Double wall--5 ply-- EE flute, BE flute, BC flute

Corrugated flute type

Paper type

The advantage of the paper packaging box is that it can be recycled and has good environmental

protection performance, and it can also use different paper materials according to customer needs.

Kraft paper has high water resistance and stain resistance; batik printing paper has a good

surface gloss, is easy to color, and has outstanding effects;

coated paper has a metallic feel, good light transmittance, and outstanding printing effects;

UV marking; embossed board is mainly used for producing colorful cards or small boxes.

In addition, there are UV light curing processing, electroplating processing, embossing printing

processing and water-based tape packaging for customers to choose.

Packaging Applications

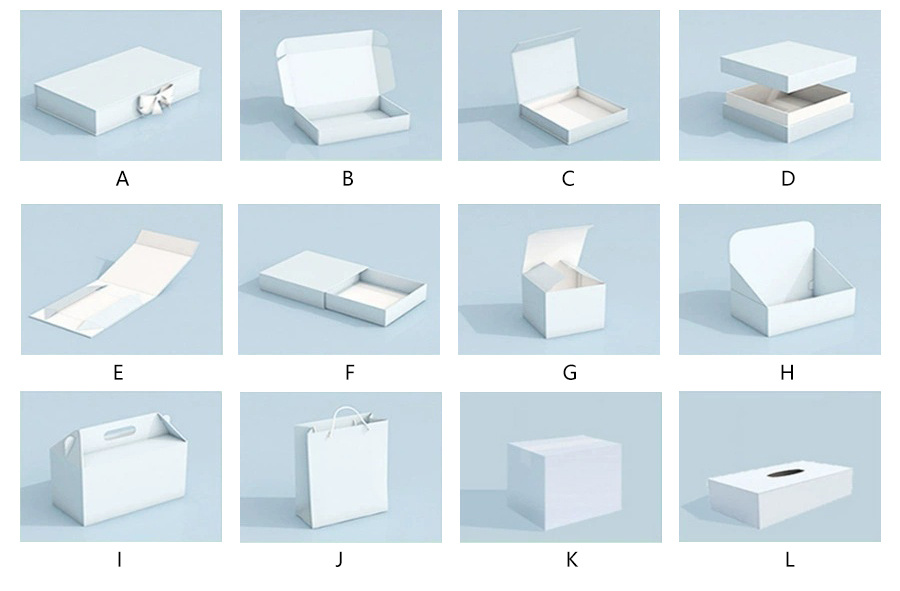

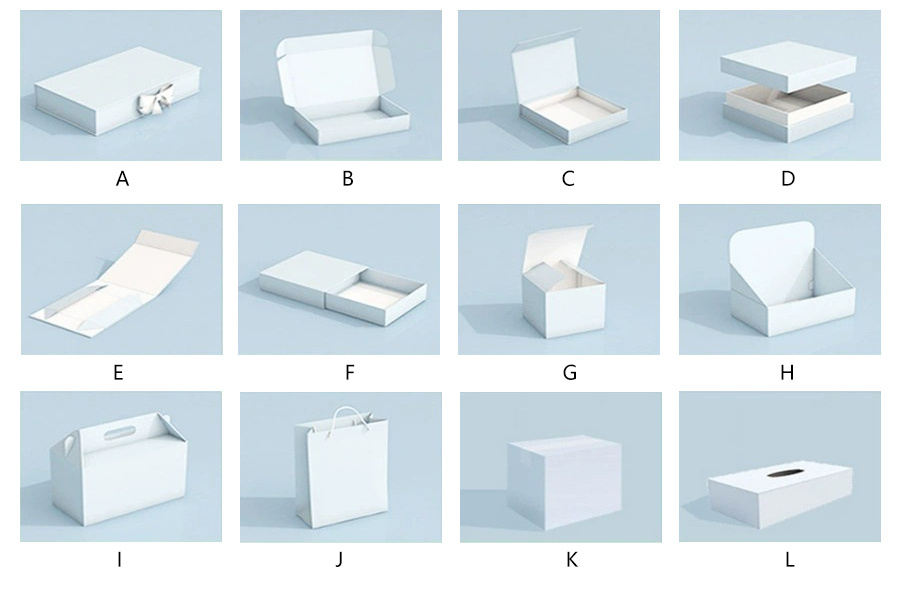

Box Type and Finish Surface

The box type as follow

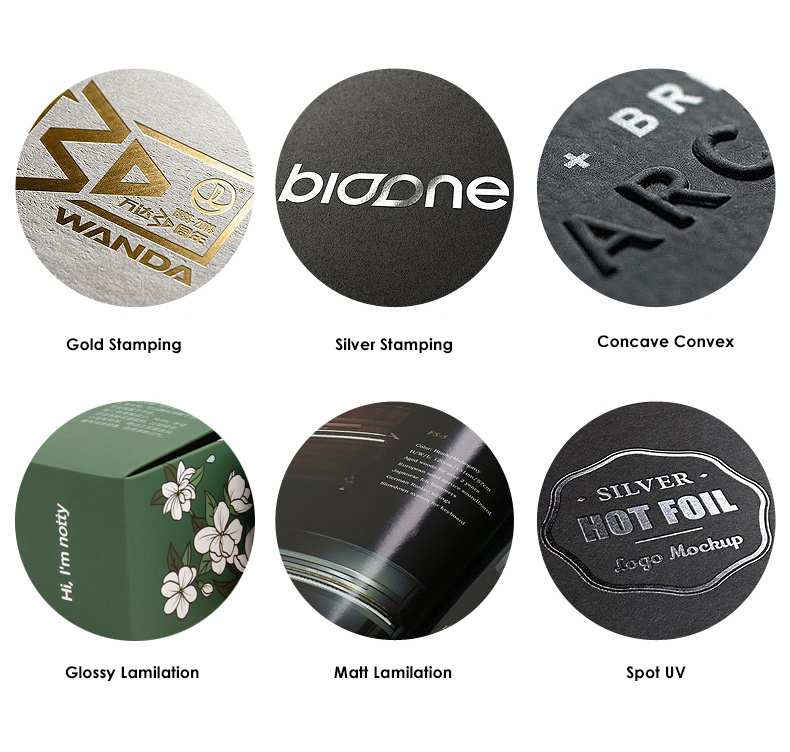

Surface treatment

Printing surface treatments give printed products their unique look, allowing them to grab attention. In the market, Matt Lamination, Gloss Lamination, Hot Stamping, Hot Silver, Spot UV and Embossing are currently the most popular printing surface treatment technologies. These technologies can be used to directly print graphics or text on promotional slogans, and can also be used to change the overall decorative style of the housing.

Different surface treatment methods will cause different effects:

Matte film: black/white/envelope/snow white/orange peel/star;

Laminated film: high gloss/thickness 0.03mm;

Bronzing: crystal gold/good gloss/good permanence;

Hot silver: shining like crystal sand / natural smell / making it born;

Spot UV: Super large UV processing area-4*5cm, high contrast, strong three-dimensional effect;

Concave-convex: 3D three-dimensional 'physical' effect, attracting eyeballs;

As a novice, if you want to choose the correct surface treatment method and achieve good results:

1) you must first make a budget carefully and choose the appropriate method according to the situation;

2) seek help from industry experts if necessary;

3) try Do some mock tests.In short, printing surface treatment is a magical knowledge; images, text or graphics can be imagined accordingly; different types of bionics can be used to present them instinctively.

Common Surface Treatment as Follows

Customer Question & Answer

Please contact customer service for more information.

Your response of following questions will help us recommend the most suitable package.

Feature: Bio-degradable paper and corrugated cardboard.

Composition: brown paper/ white paper + different layer corrugated board+ brown /white paper

Common corrugated board: single wall –3 ply–F flute, E flute, B flute, C flute Double wall–5 ply– EE flute, BE flute, BC flute

Corrugated flute type

Paper type

The advantage of the paper packaging box is that it can be recycled and has good environmental

protection performance, and it can also use different paper materials according to customer needs.

Kraft paper has high water resistance and stain resistance; batik printing paper has a good

surface gloss, is easy to color, and has outstanding effects;

coated paper has a metallic feel, good light transmittance, and outstanding printing effects;

UV marking; embossed board is mainly used for producing colorful cards or small boxes.

In addition, there are UV light curing processing, electroplating processing, embossing printing

processing and water-based tape packaging for customers to choose.

Packaging Applications

The box type as follow

Surface treatment

Printing surface treatments give printed products their unique look, allowing them to grab attention. In the market, Matt Lamination, Gloss Lamination, Hot Stamping, Hot Silver, Spot UV and Embossing are currently the most popular printing surface treatment technologies. These technologies can be used to directly print graphics or text on promotional slogans, and can also be used to change the overall decorative style of the housing.

Different surface treatment methods will cause different effects:

Matte film: black/white/envelope/snow white/orange peel/star;

Laminated film: high gloss/thickness 0.03mm;

Bronzing: crystal gold/good gloss/good permanence;

Hot silver: shining like crystal sand / natural smell / making it born;

Spot UV: Super large UV processing area-4*5cm, high contrast, strong three-dimensional effect;

Concave-convex: 3D three-dimensional ‘physical’ effect, attracting eyeballs;

As a novice, if you want to choose the correct surface treatment method and achieve good results:

1) you must first make a budget carefully and choose the appropriate method according to the situation;

2) seek help from industry experts if necessary;

3) try Do some mock tests.In short, printing surface treatment is a magical knowledge; images, text or graphics can be imagined accordingly; different types of bionics can be used to present them instinctively.

Common Surface Treatment as Follows