Factory Custom White Cardboard Corrugated Packaging Carton Transport Box for Milk

Description

Kraft paper packaging can be recycled, which can effectively reduce the consumption of forest resources.

Kraft paper is natural and retro in color, which can meet the needs of different brands. It can have a good visual effect without complicated printing.

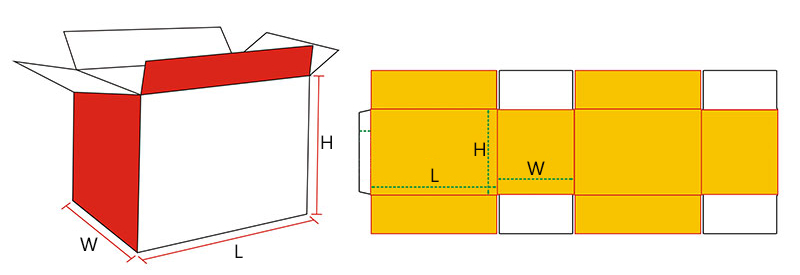

Flat box expansion structure.

Basic Info

|

Product Name |

Milk Carton Box |

Surface Handling |

Glossy lamination, Matte lamination |

|

Box Style |

OEM |

Logo Printing |

Customized Logo |

|

Material Structure |

White Board + Corrugated Paper + White Board/Kraft Paper |

Origin |

Ningbo |

|

Flute Type |

E flute, B flute, BE flute |

Sample |

Accept custom samples |

|

Shape |

Rectangle |

Sample Time |

5-7 Working Days |

|

Color |

CMYK Color, Pantone Color |

Production Lead Time |

10-15 days based on quantity |

|

Printing |

Offset Printing |

Transport Package |

Strong 5 ply Corrugated Carton |

|

Type |

Two Sides Printing Box |

MOQ |

2000PCS |

Detailed Images

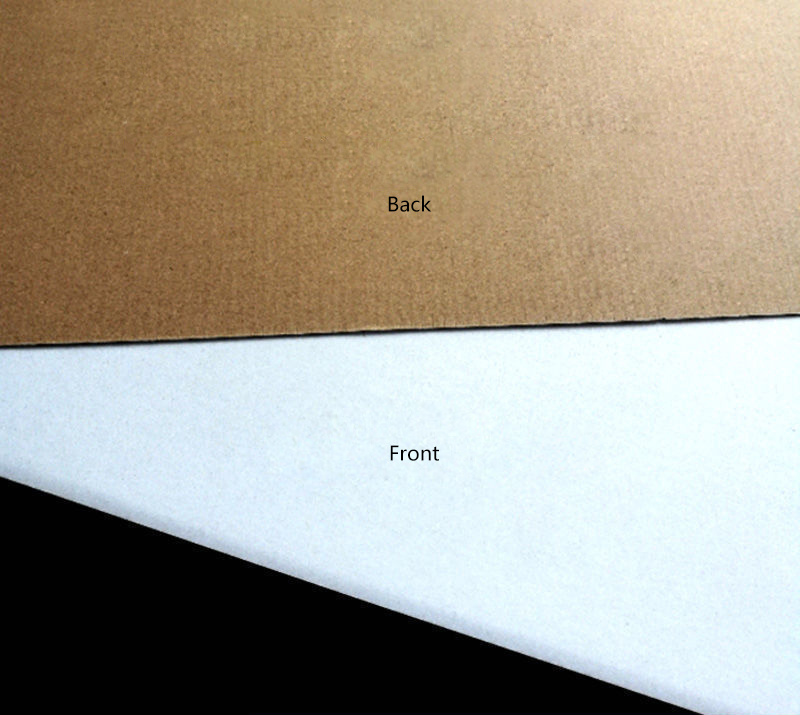

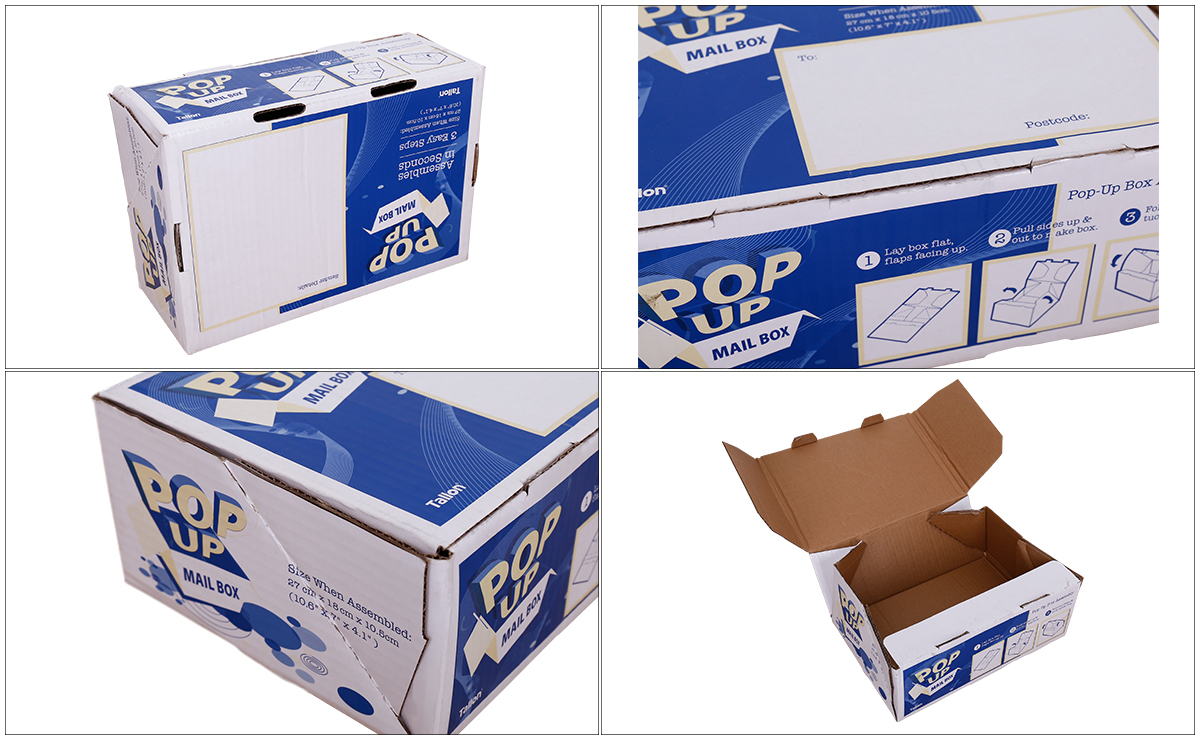

Corrugated cardboard with white on one side.

The waste can be recycled without white pollution.

Flexographic printing kraft paper box is printed directly on kraft corrugated cardboard. The color is relatively simple and the price is low.

Offset printing kraft paper box needs to be printed on kraft paper first, and then mounted on kraft corrugated cardboard. This printing method has beautiful and rich colors.

Offset Printing Kraft Paper Box & Flexographic Printing Kraft Paper Box

Material Structure and Application

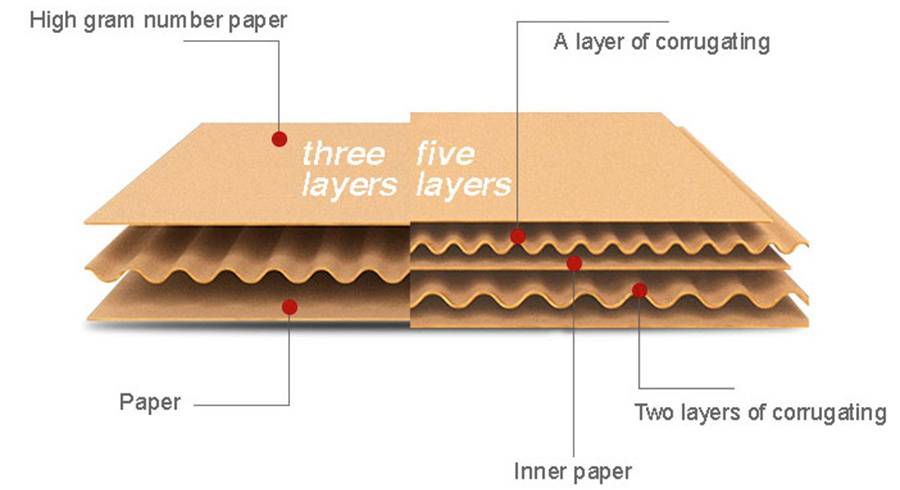

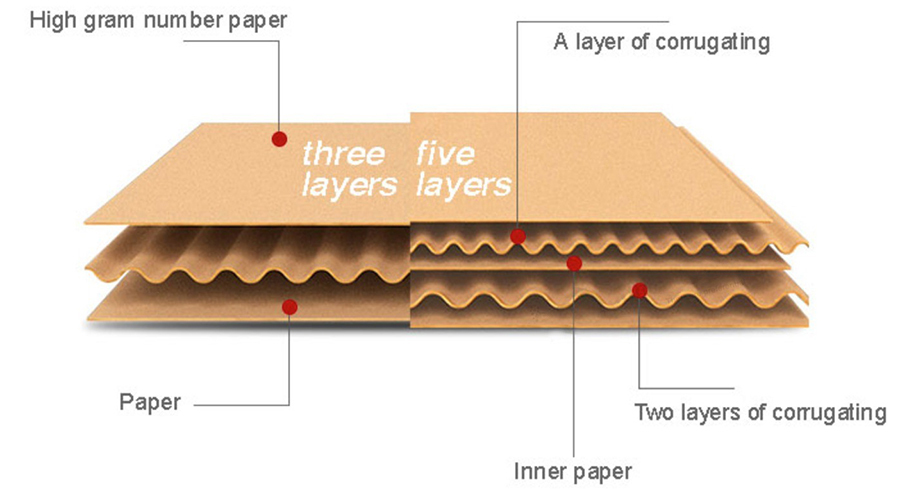

Three-layer and five-layer corrugated cardboard are commonly used in the production of carton boxes.

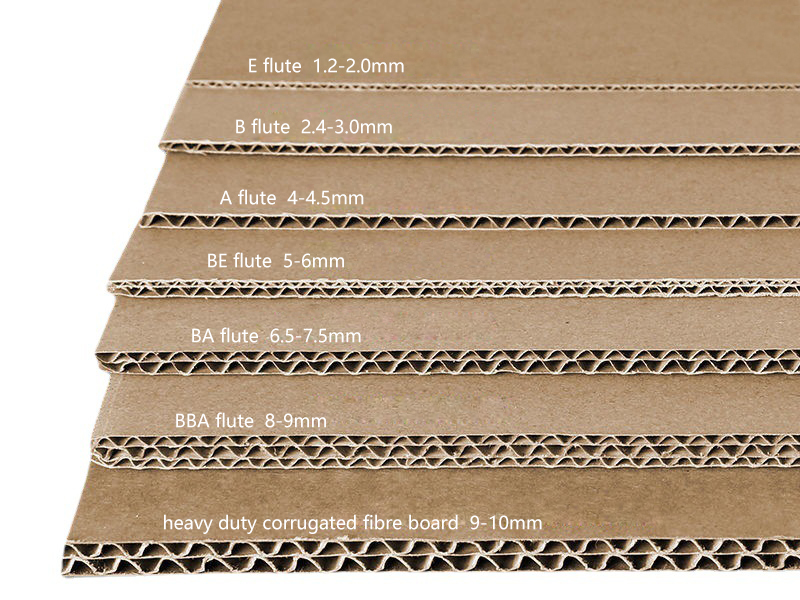

Corrugated boards with different corrugated shapes have different functions.

The front is white corrugated cardboard.

Structural Drawing of Corrugated Cardboard

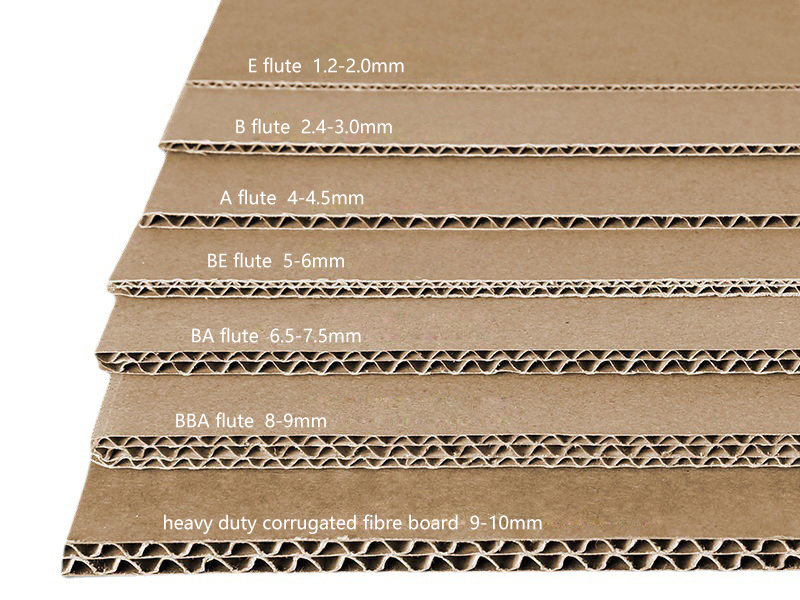

Thickness diagram of some corrugated types.

Packaging Applications

It is used for transportation packaging of heavy products.

Box Type and Finish Surface

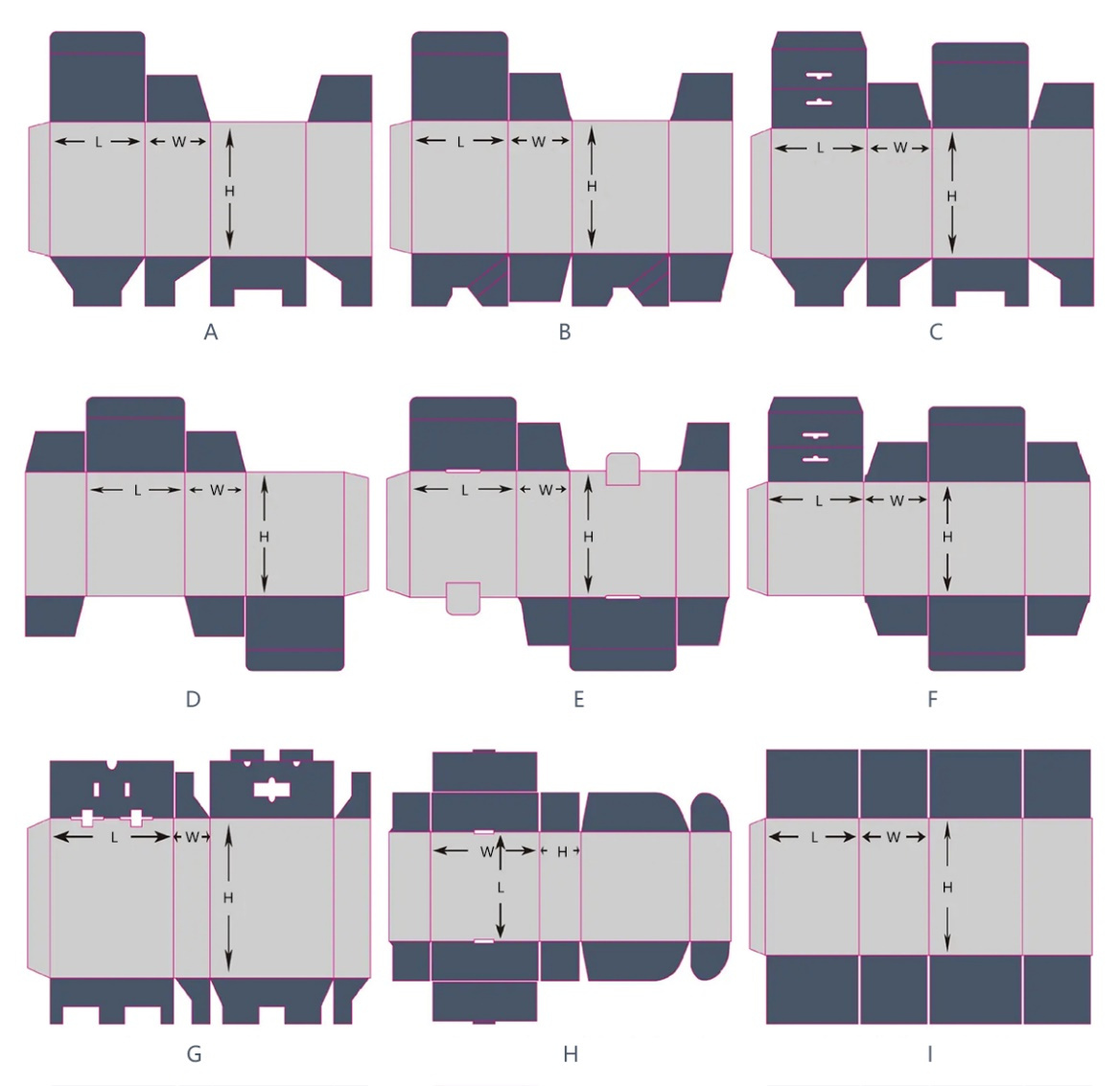

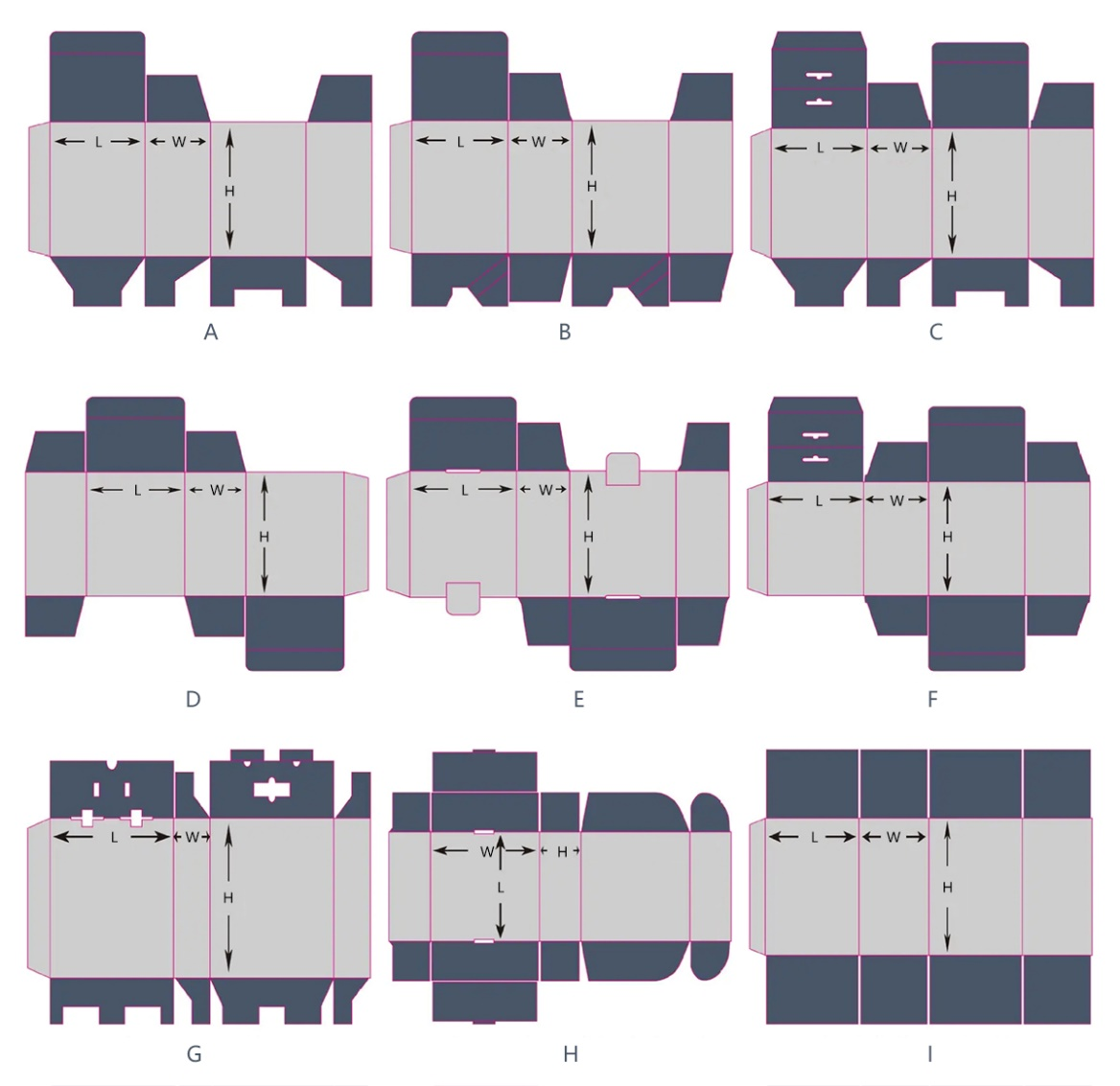

Box structure can be customized according to your requirements.

The box type as follow

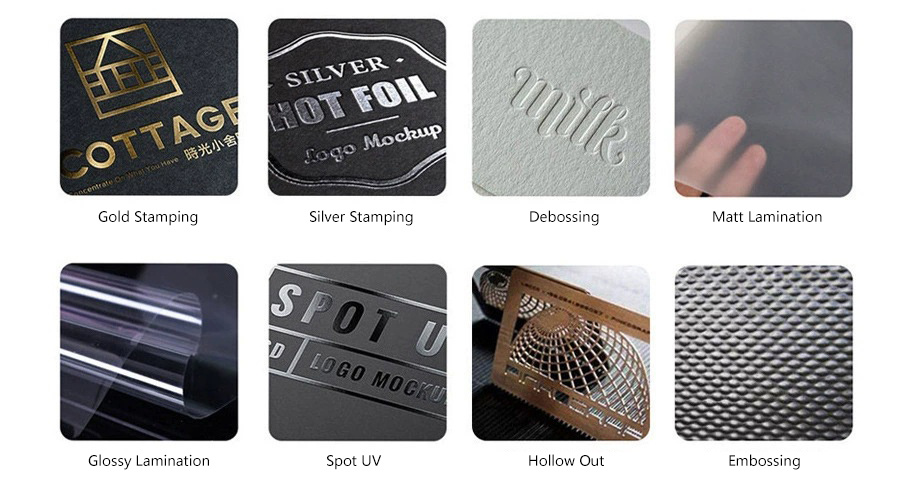

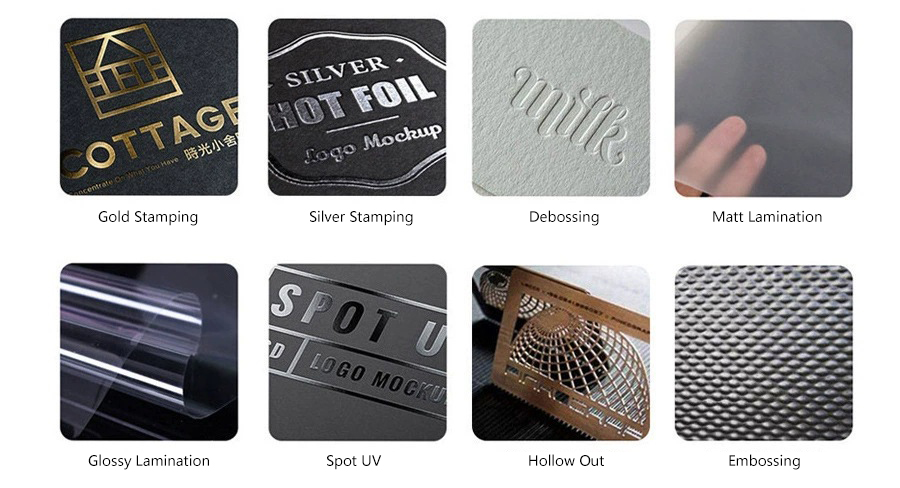

Finish Surface

The most popular surface preparation technique is lamination. The cost is reasonable, and the outcome is favorable. In order to protect printed materials and improve their shine, hot pressing transparent plastic film is used as lamination. The different kinds of laminated films include glossy films, matte films, tactile films, laser films, detachable films, etc.

In addition to lamination treatment, the surface of printed matter can also be given a "varnishing" treatment, which can shield it from fading and dirt and extend the useful life of tag printed materials.

Common Surface Treatment as Follows

Customer Question & Answer

Please contact customer service for more information.

Your response of following questions will help us recommend the most suitable package.

Corrugated cardboard is made of face paper, inner paper, medium paper and corrugated paperboard through bonding.

Three-layer and five-layer corrugated cardboard are commonly used in the production of carton boxes.

Corrugated boards with different corrugated shapes have different functions.

The front is white corrugated cardboard.

Structural Drawing of Corrugated Cardboard

Thickness diagram of some corrugated types.

Box structure can be customized according to your requirements.

The box type as follow

Finish Surface

The most popular surface preparation technique is lamination. The cost is reasonable, and the outcome is favorable. In order to protect printed materials and improve their shine, hot pressing transparent plastic film is used as lamination. The different kinds of laminated films include glossy films, matte films, tactile films, laser films, detachable films, etc.

In addition to lamination treatment, the surface of printed matter can also be given a “varnishing” treatment, which can shield it from fading and dirt and extend the useful life of tag printed materials.

Common Surface Treatment as Follows