Custom Size White Cardboard Paper Box With Outer Sleeve

Description

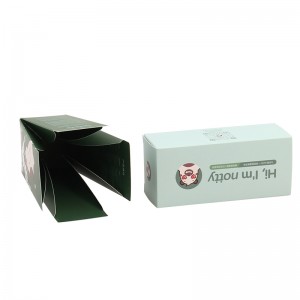

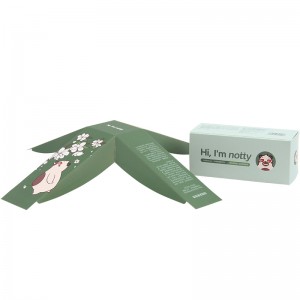

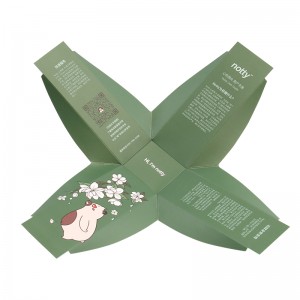

This is a white cardboard paper box, the inner box is folding type, with a outer sleeve. Flat shipping. Fold it up along creases. This kind of box can be used to pack daily necessities, chocolate bar, tea , coffee, cosmetic, etc.

Basic Info.

|

Product Name |

Cardboard Paper Box |

Surface Treatment |

Glossy/Matte Lamination or Varnish, spot UV, etc. |

|

Box Style |

Folding box |

Logo Printing |

Customized Logo |

|

Material Structure |

Paperboard, 250gsm, 300gsm, 350gsm, 400gsm, etc. |

Origin |

Ningbo city, China |

|

Weight |

Lightweight box |

Sample type |

Printing sample, or no print. |

|

Shape |

Rectangle |

Sample Lead Time |

2-5 working days |

|

Color |

CMYK Color, Pantone Color |

Production Lead Time |

12-15 natural days |

|

Printing mode |

Offset Printing |

Transport Package |

Standard export carton |

|

Type |

Double-sided Printing Box |

MOQ |

2,000PCS |

Detailed Images

These details are used to show the quality, such as materials, printing and surface treatment.

Customer Question & Answer

Please contact customer service for more information.

Your response of following questions will help us recommend the most suitable package.

Material Structure and Application

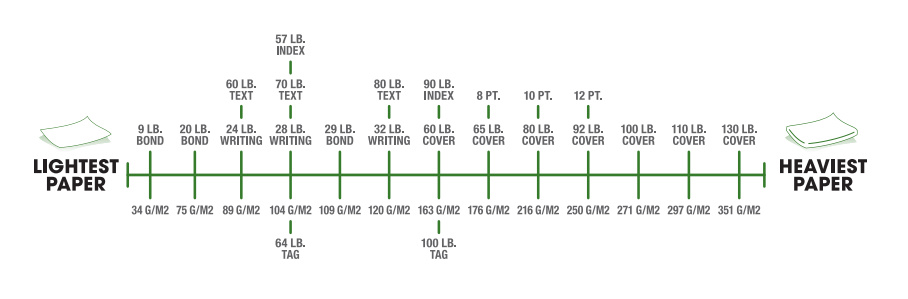

Paperboard is a thick paper-based material. While there is no rigid differentiation between paper and paperboard, paperboard is generally thicker (usually over 0.30 mm, 0.012 in, or 12 points) than paper and has certain superior attributes such as foldability and rigidity. According to ISO standards, paperboard is a paper with a grammage above 250 g/m2, but there are exceptions. Paperboard can be single- or multi-ply.

Paperboard can be easily cut and formed, is lightweight, and because it is strong, is used in packaging. Another end-use is high quality graphic printing, such as book and magazine covers or postcards.

Sometimes it is referred to as cardboard, which is a generic, lay term used to refer to any heavy paper pulp–based board, however this usage is deprecated in the paper, printing and packaging industries as it does not adequately describe each product type.

Terminology and classifications of paperboard are not always uniform. Differences occur depending on specific industry, locale, and personal choice. In general, the following are often used:

Boxboard or cartonboard: paperboard for folding cartons and rigid set-up boxes.

Folding boxboard (FBB): a bending grade capable of being scored and bending without fracture.

Kraft board: a strong virgin fiber board often used for beverage carriers. Often clay-coated for printing.

Solid bleached sulphate (SBS): clean white board used for foods etc. Sulphate refers to the kraft process.

Solid unbleached board (SUB): board made from unbleached chemical pulp.

Containerboard: a type of paperboard manufactured for the production of corrugated fiberboard.

Corrugated medium: the inner fluted portion of corrugated fiberboard.

Linerboard: a strong stiff board for one or both sides of corrugated boxes. It is the flat covering over the corrugating medium.

Other

Binder’s board: a paperboard used in bookbinding for making hardcovers.

Packaging Applications

Box Type and Finish Surface

The surface treatment process of printed products generally refers to the post-processing process of printed products, in order to make the printed products more durable, convenient for transportation and storage, and look more high-end, atmospheric and high-grade. Printing surface treatment includes: lamination, spot UV, gold stamping, silver stamping, concave convex, embossing, hollow-carved, laser technology, etc.

Common Surface Treatment As Follows

Paper Type

White Card Paper

Both sides of the white card paper are white. The surface is smooth and flat, the texture is hard, thin and crisp, and can be used for double-sided printing. It has relatively uniform ink absorption and folding resistance.

Coated Art Paper

Coated paper has smooth surface, high whiteness and good ink absorption performance. It is mainly used for printing advanced picture books, calendars and books, etc.